Re-use of this resource is governed by a Creative Commons

Attribution-

NonCommercial-ShareAlike 4.0 International

https://creativecommons.org/licenses/by-nc-sa/4.0/

NonCommercial-ShareAlike 4.0 International

https://creativecommons.org/licenses/by-nc-sa/4.0/

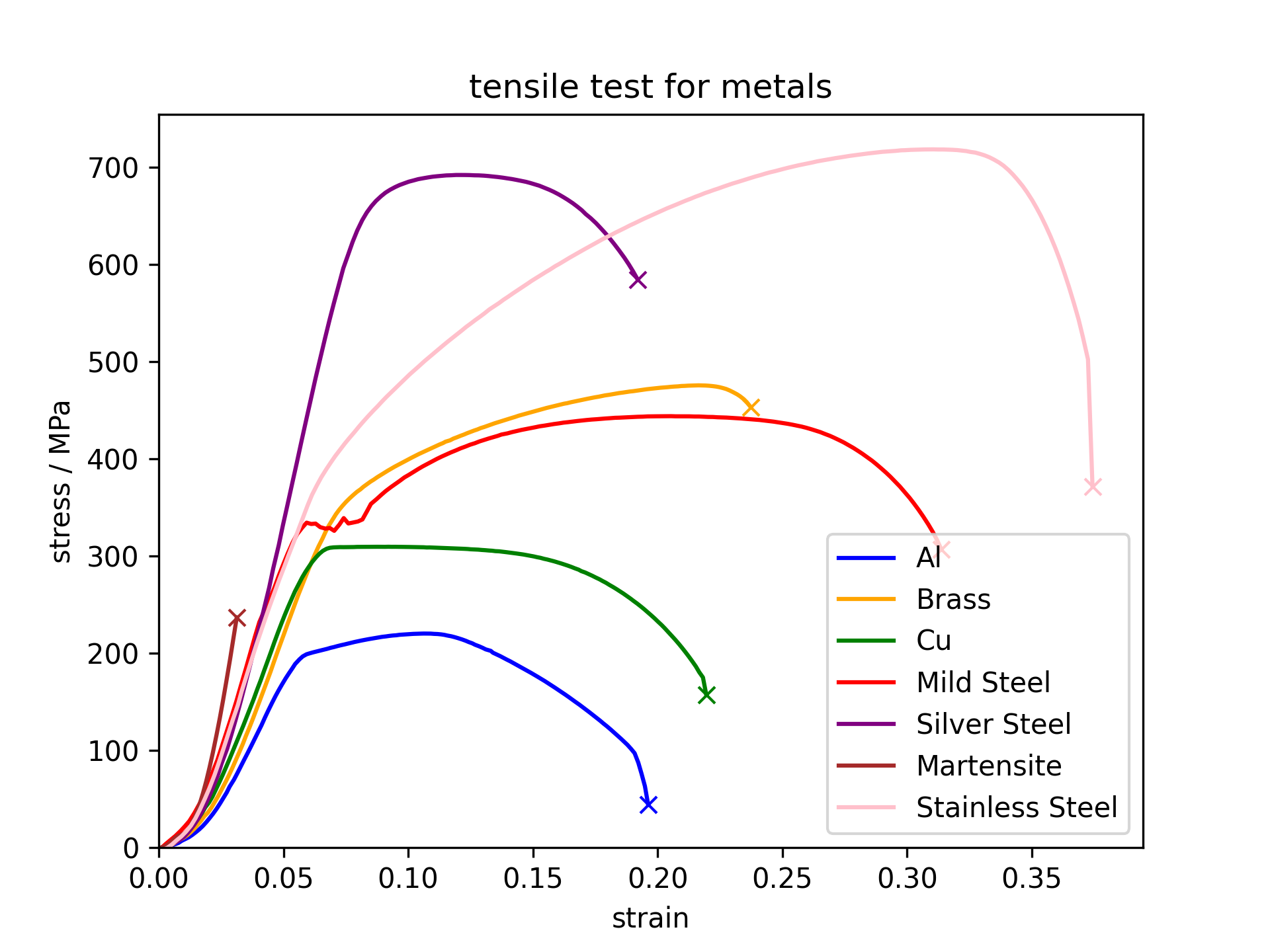

Tensile test for metals and alloys

Select the materials

to test in a tensometer:

Approximately pure aluminium.

Approximately pure copper.

Cu-46 wt% Zn α-β brass.

Fe-C alloy with lower carbon content.

Fe-C alloy with higher carbon content.

Made from silver steel annealed at 750 ℃ and rapidly quenched in water.

18.7-Cr, 70.1-Fe, 11.1-Ni wt% alloy.

A summary to compare the mechanical behaviour of the metallic materials above.

Approximately pure aluminium.

Approximately pure copper.

Cu-46 wt% Zn α-β brass.

Fe-C alloy with lower carbon content.

Fe-C alloy with higher carbon content.

Made from silver steel annealed at 750 ℃ and rapidly quenched in water.

18.7-Cr, 70.1-Fe, 11.1-Ni wt% alloy.

A summary to compare the mechanical behaviour of the metallic materials above.

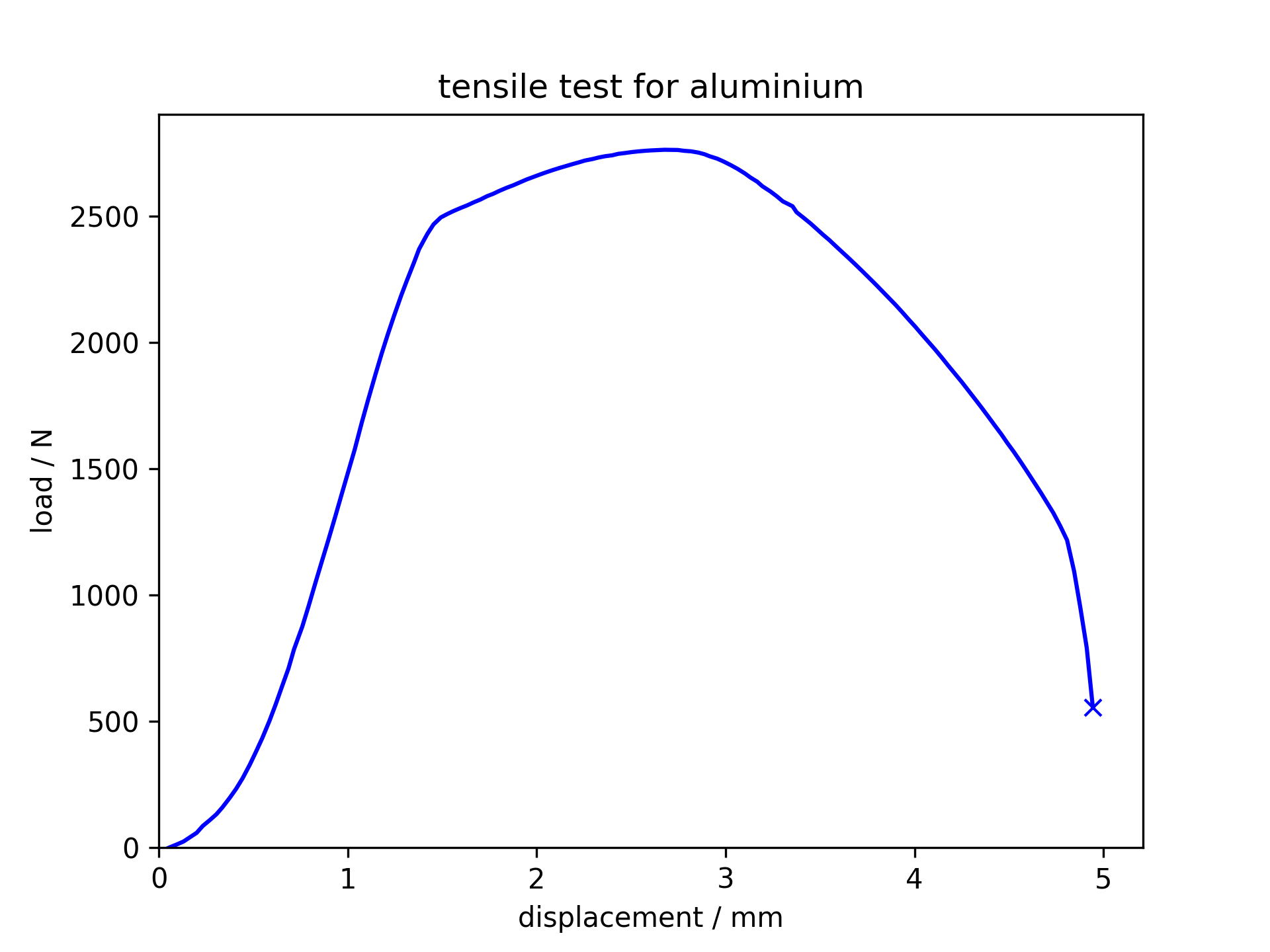

Tensile test for aluminium

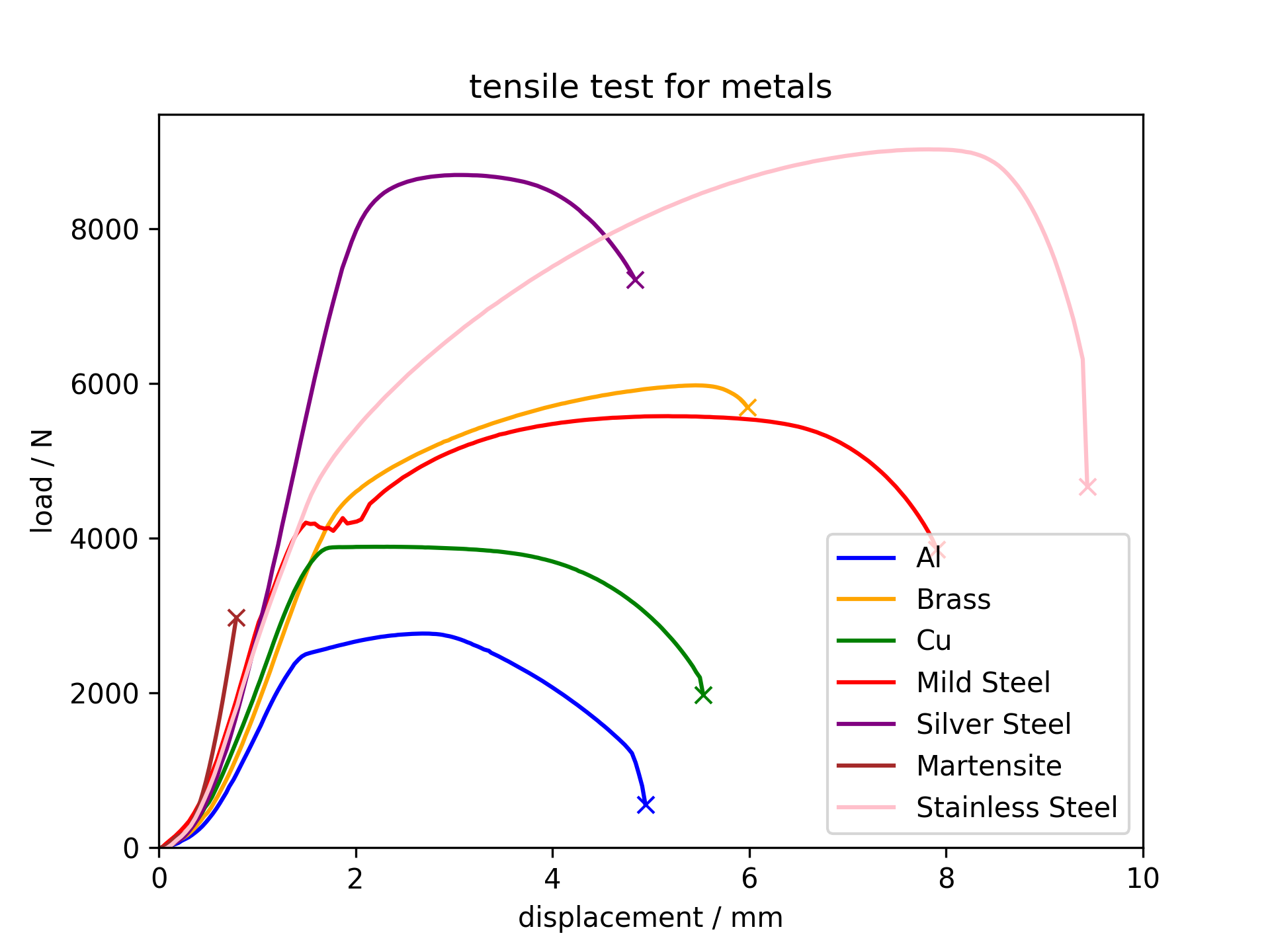

Aluminium is ductile and necks before fracture.

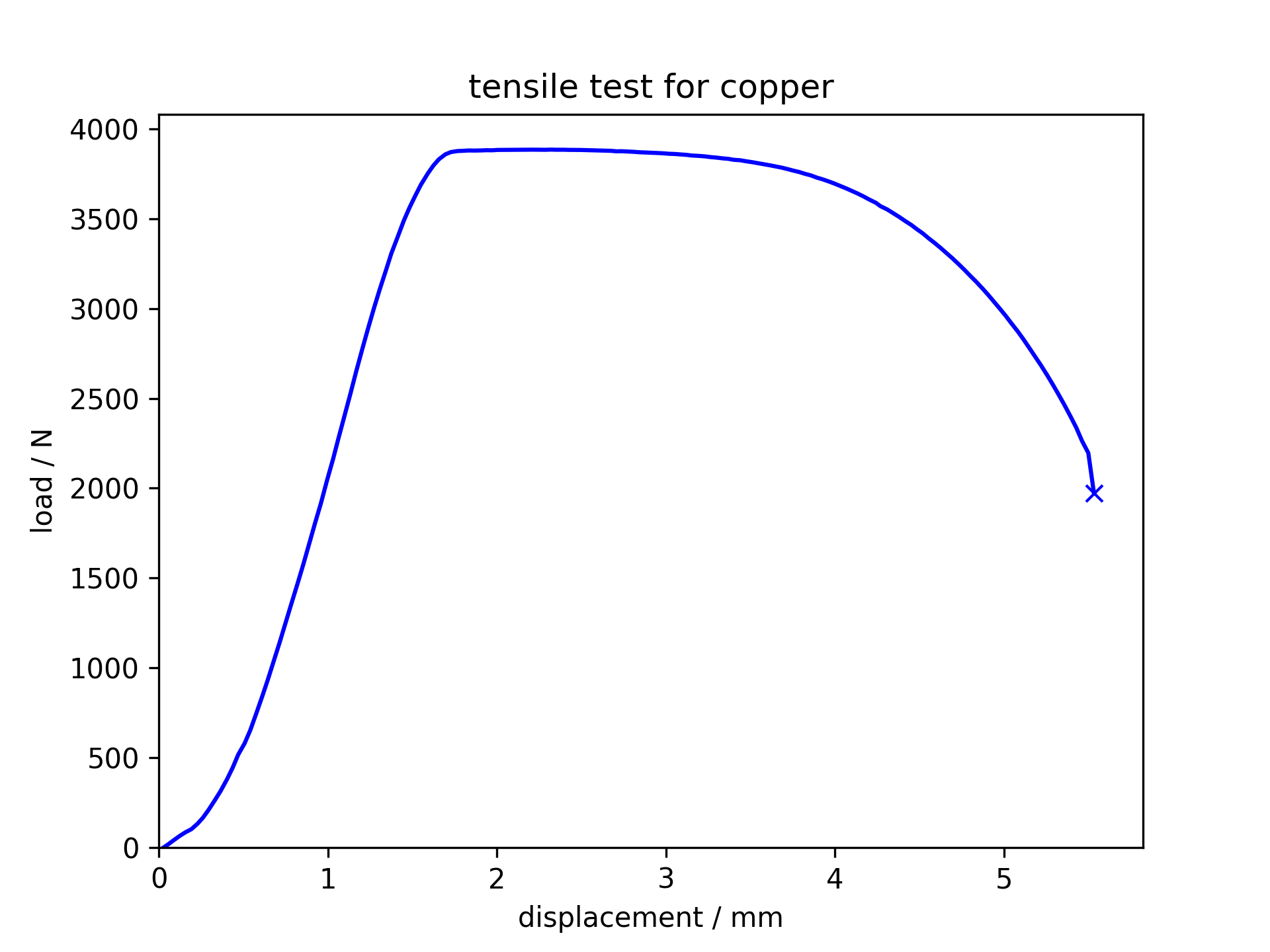

Tensile test for copper

Copper is ductile

and necks before fracture.

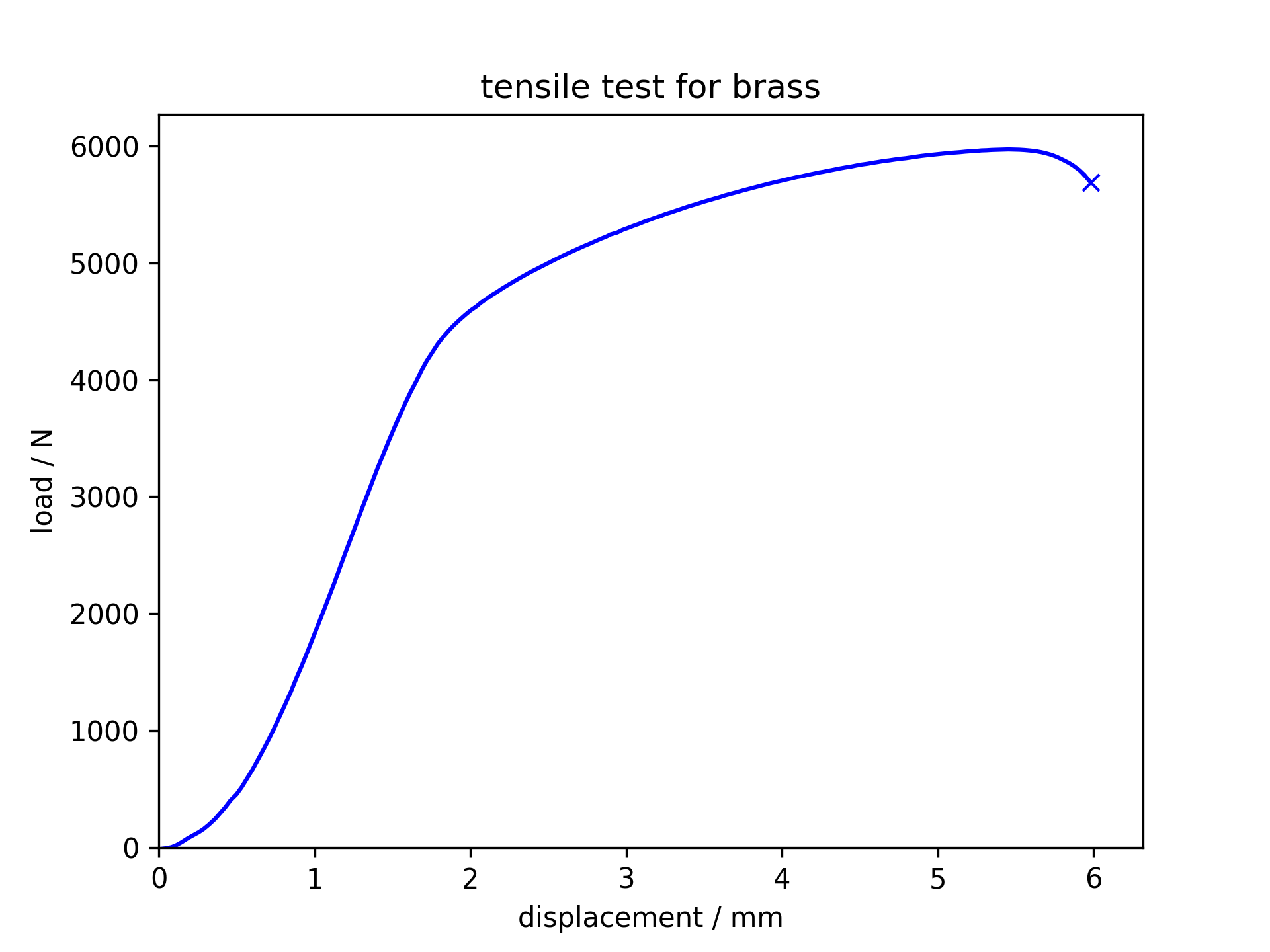

Tensile test for brass

The brass is tougher

and can be stretched longer without failing. It is also more brittle

and does not neck significantly before fracture.

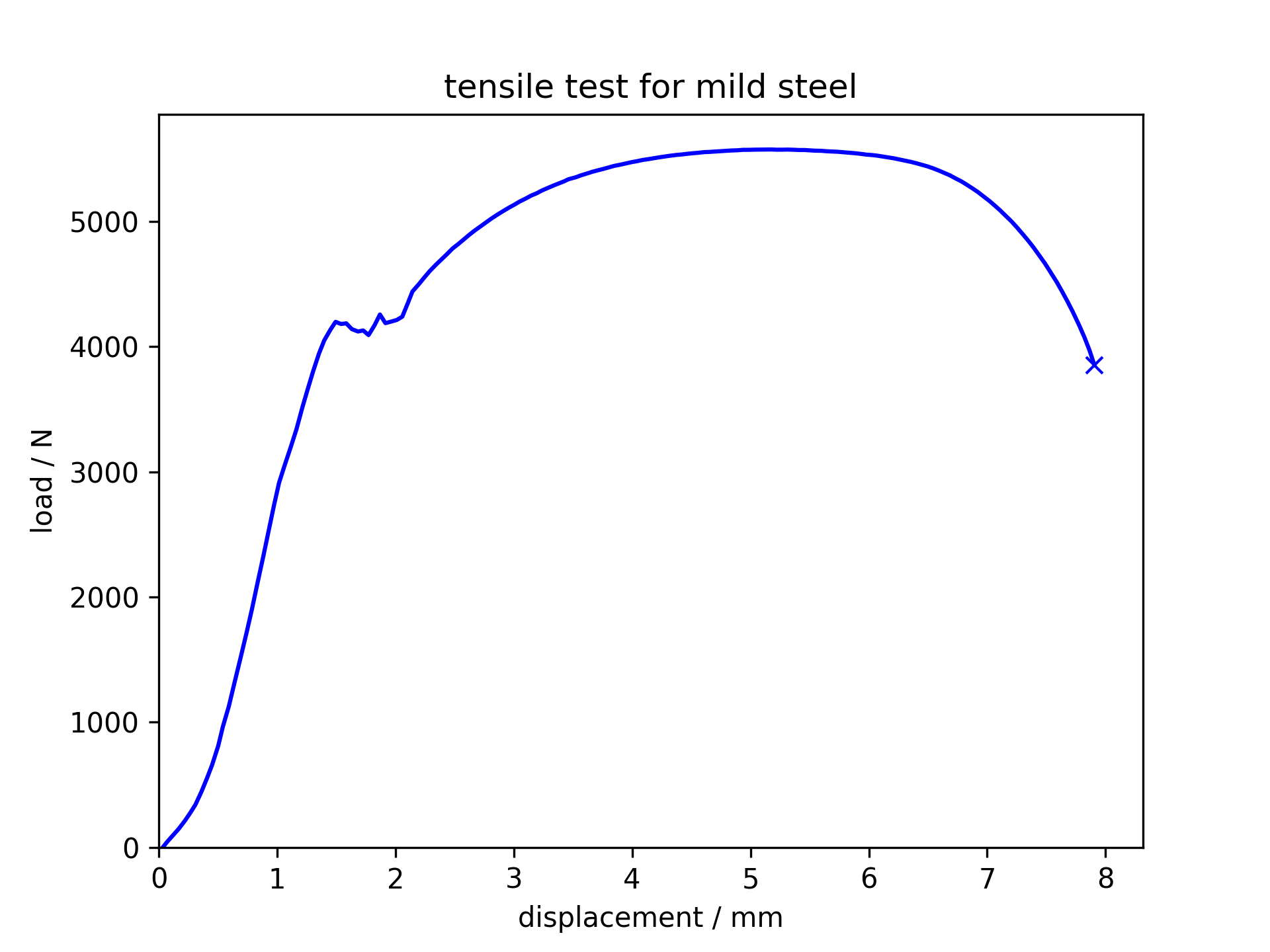

Tensile test for mild steel

This low carbon

steel shows a pronounced drop in the stress required for plastic deformation

following initial yield. To learn the reasons behind this, click

.

Cottrell atmosphere

When the alloy is made,

at high temperatures allows the carbon solute atoms to diffuse towards the

dislocations where there is more open space.

This creates a Cottrell atmosphere along the length of a dislocation, which pins the dislocations, retarding their movement. This results in a higher initial yield stress.

After the dislocations escape from their Cottrell atmospheres, the yield stress drops.

This creates a Cottrell atmosphere along the length of a dislocation, which pins the dislocations, retarding their movement. This results in a higher initial yield stress.

After the dislocations escape from their Cottrell atmospheres, the yield stress drops.

The general increase in yield stress after the drop is due to work hardening

(see hardness section).

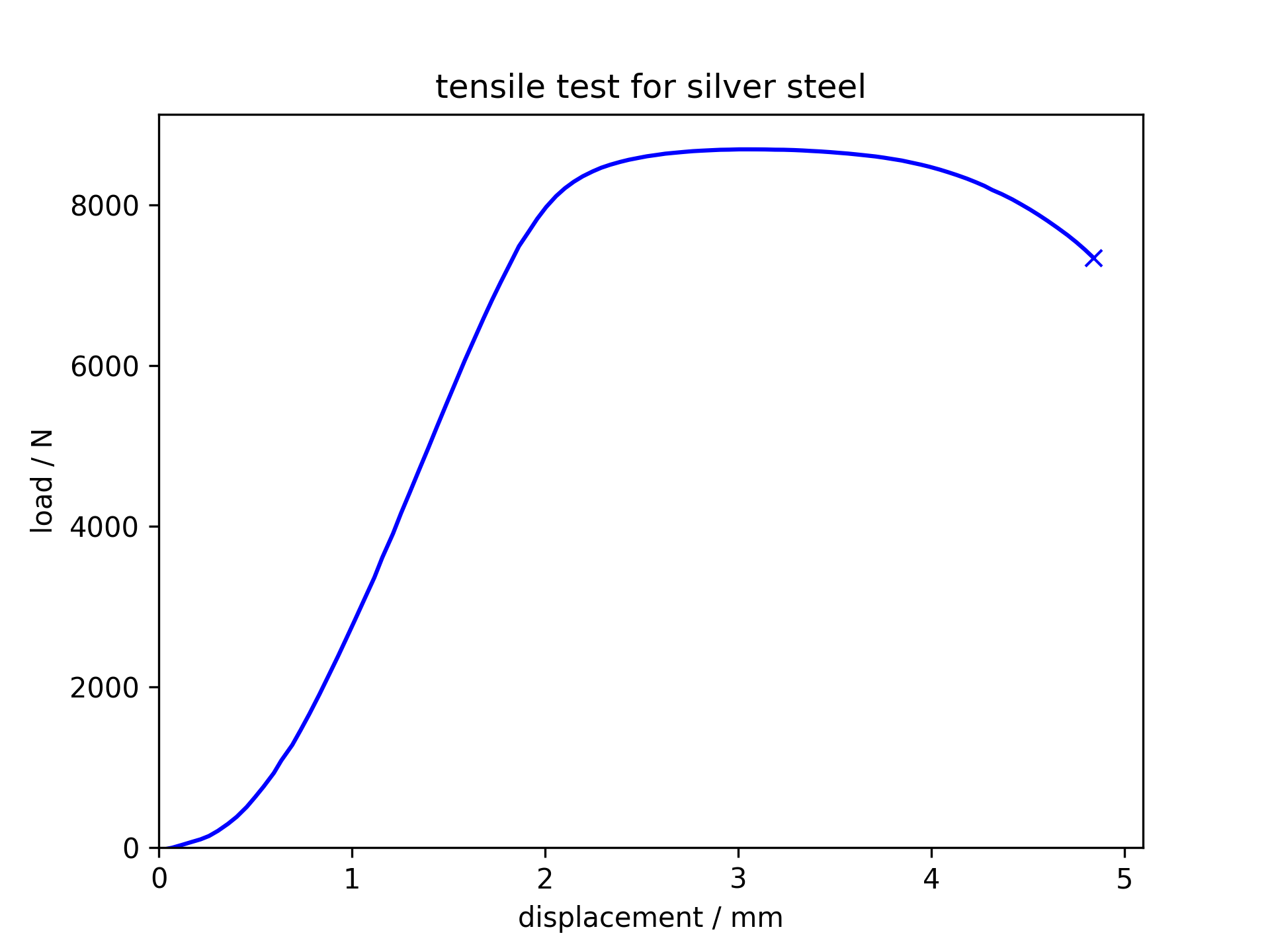

Tensile test for silver steel

Silver steel is

more brittle than mild steel and undegoes less necking compared to mild

steel.

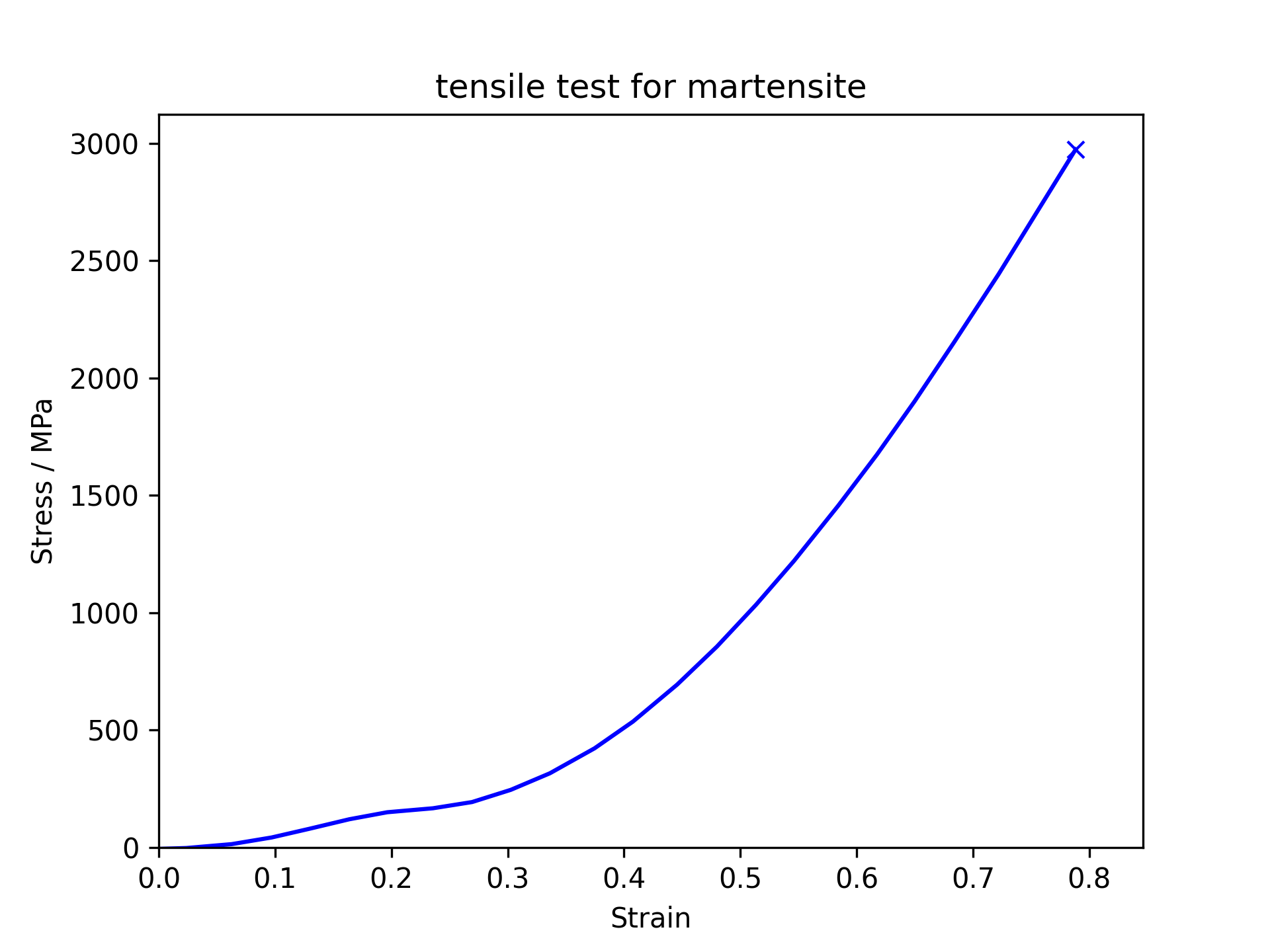

Tensile test for martensite

Martensite is very

brittle and hardly undergoes any plastic deformation before fracture.

Its yield stress is lower than silver steel as a result of residual

stress from quenching.

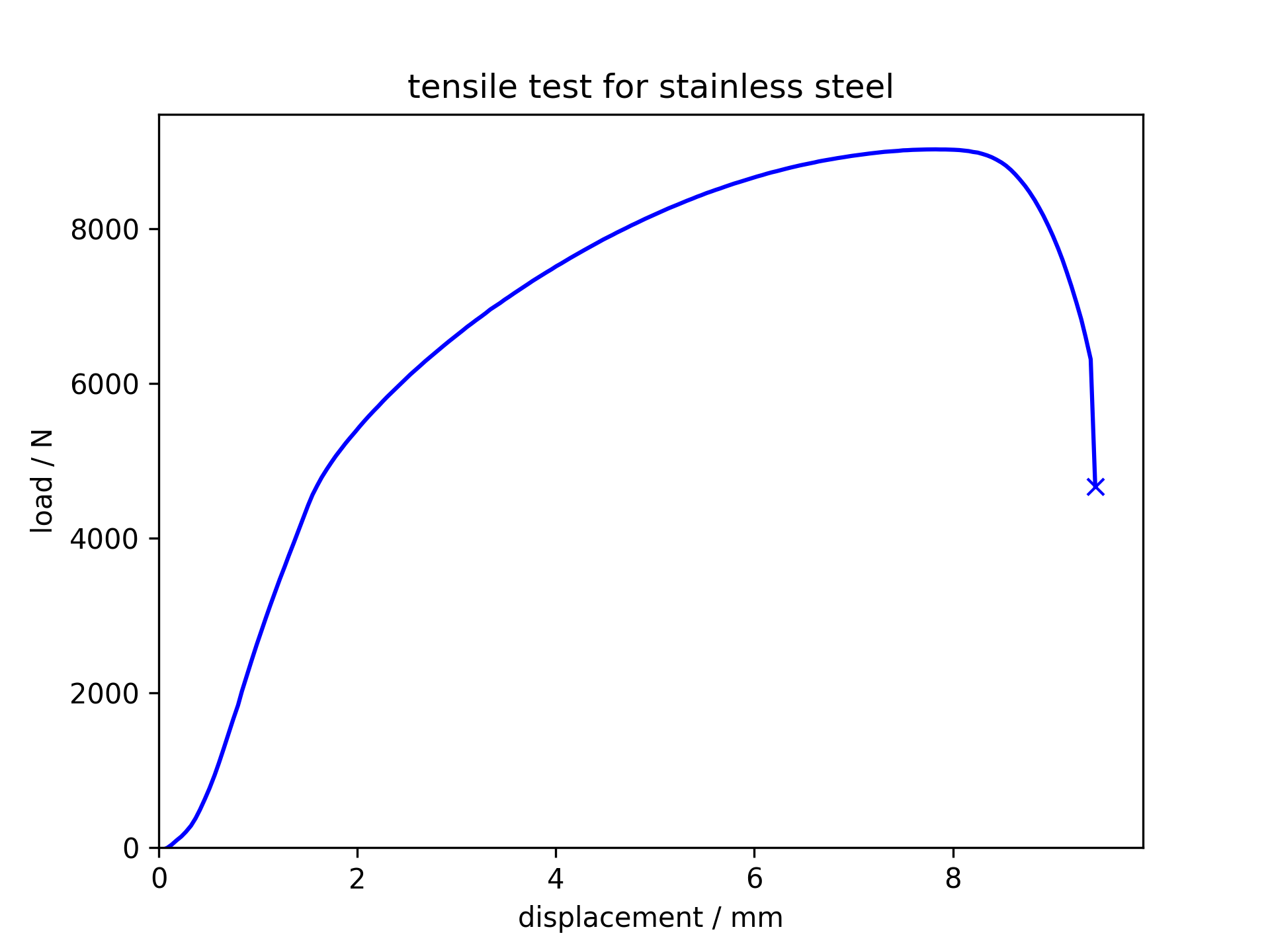

Tensile test for stainless steel

Stainless steel

is ductile and tough. It can be streched for a large length and absorb

a lot of energy before fracture. It also necks before fracture.

Load and displacement curves for different metallic samples

Stress and strain curves for different metallic samples