Freckles in Nickel Based Superalloys

H. K. D. H. Bhadeshia

Abstract

Many turbine blades for the highest temperature portions of jet engines are cast in the form of single crystals of nickel based superalloys. The single-crystal nature of the blade can be disrupted by the accidental formation of stray grains. The latter are known as freckles,, small equiaxed grains which appear on the blade in clusters aligned to the direction in which the solidifying blade is withdrawn from the hot-zone of the casting furnace.

One reason why freckles arise is because chemical segregation during solidification leads to differences in density within the liquid. These drive fluid flow which cause dendrite arms to fracture. The fractured segments then grow into the freckles.

Examples of Freckles

The following images have kindly been provided by Dr A Mitchell,

Professor Emeritus of Metallurgical Engineering,

Department of Metals and Materials Engineering,

University of British Columbia, Canada. They are all of polycrystalline metals.

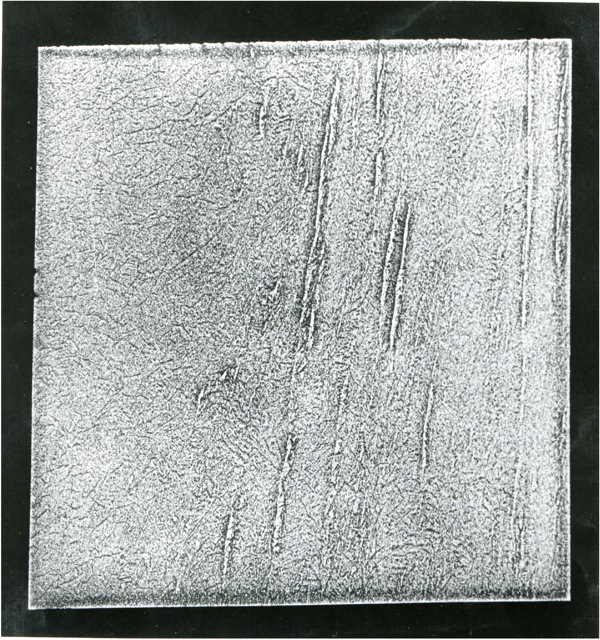

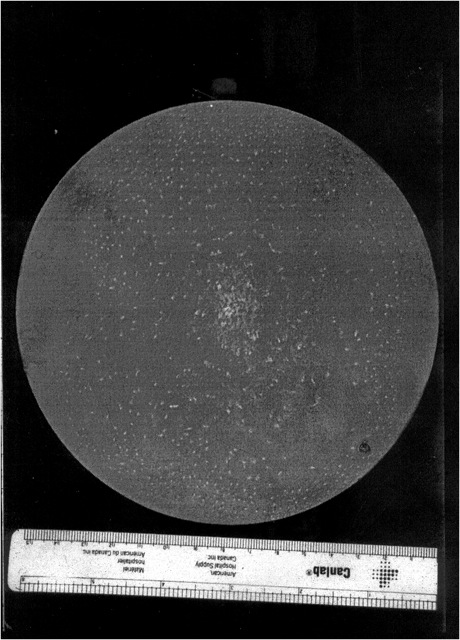

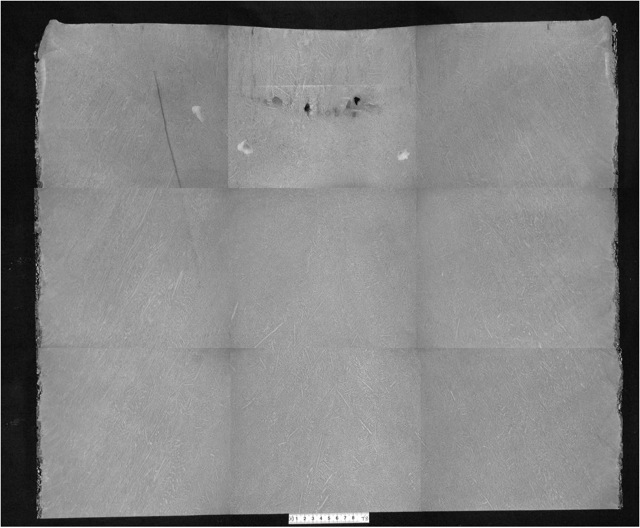

Freckles in an electro-slag refined 800 mm ingot of 18Cr18Mn steel |

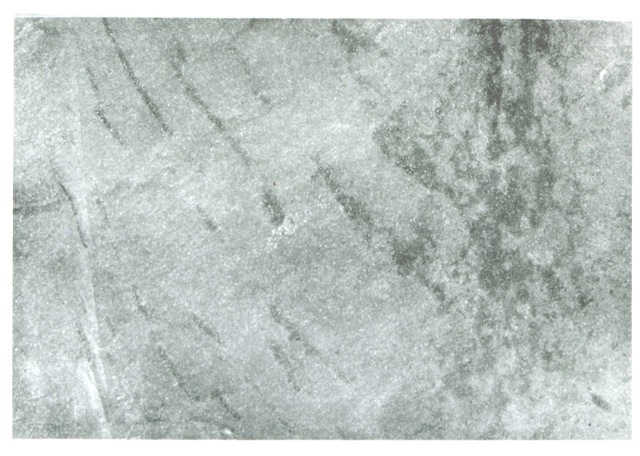

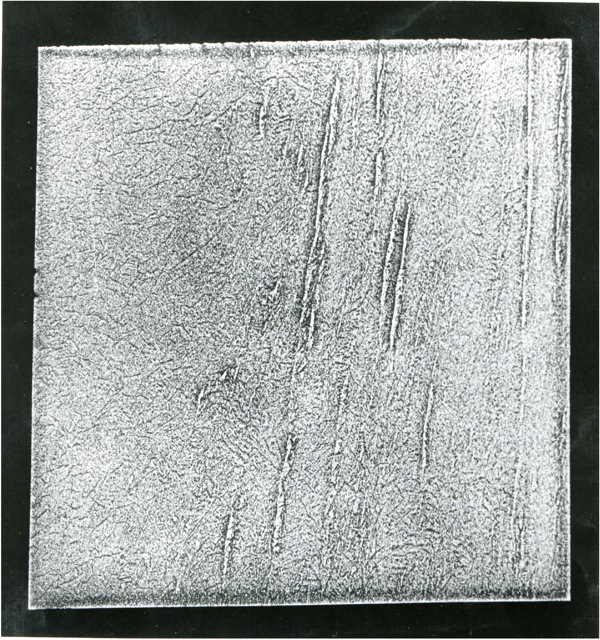

Axial section showing freckles in IN 718, 200 mm diameter billet |

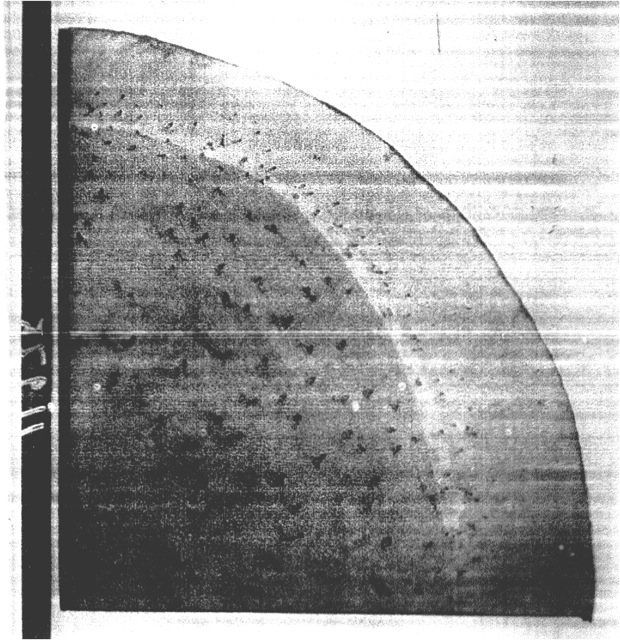

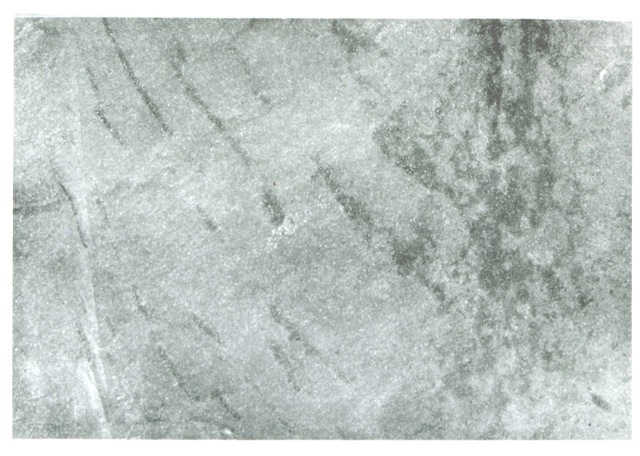

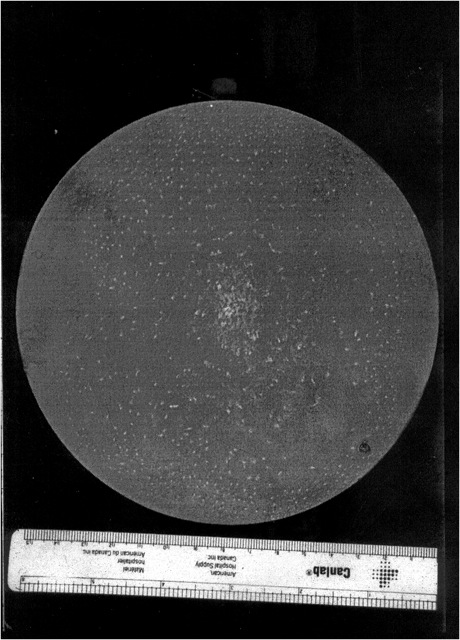

Radial section showing freckles in IN 718, 200 mm diameter billet |

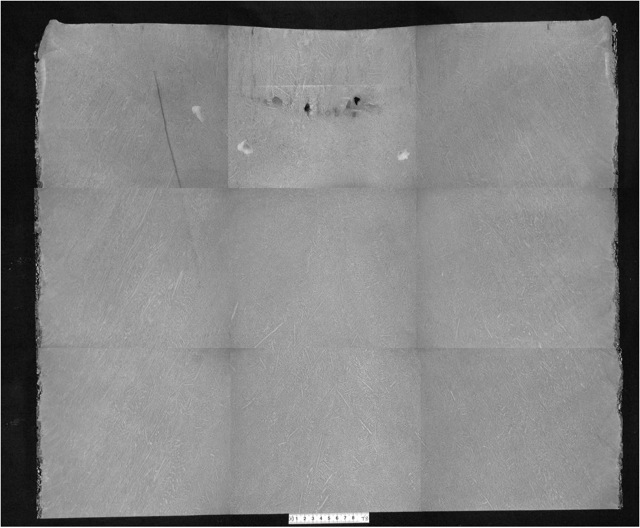

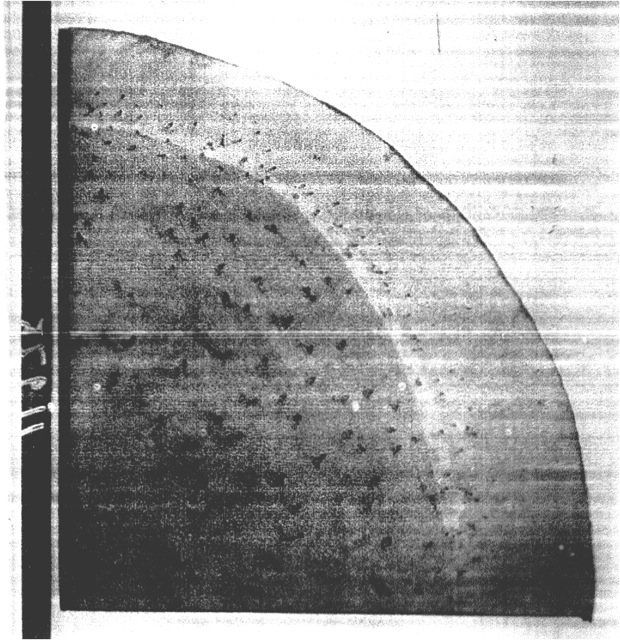

Isolated freckle in a 900 mm vacuum arc refined ingot of 300M martensitic steel |

Beta freckles in a Ti-17 alloy billet, formed by the same mechanism as in IN718 |