The gas container on the right is made using dual-phase steel DP600, and hence is much lighter than that fabricated using conventional steel. The two cylinders are connected by a rope and pully to illustrate the weight advantage.

The term dual phase steel generally refers to a alloys with a mixed microstructure of ferrite and martensite. Such steels are characterised by good formability and strength and have applications primarily in the automobile industries.

Gas containers made using dual-phase steel DP600. |

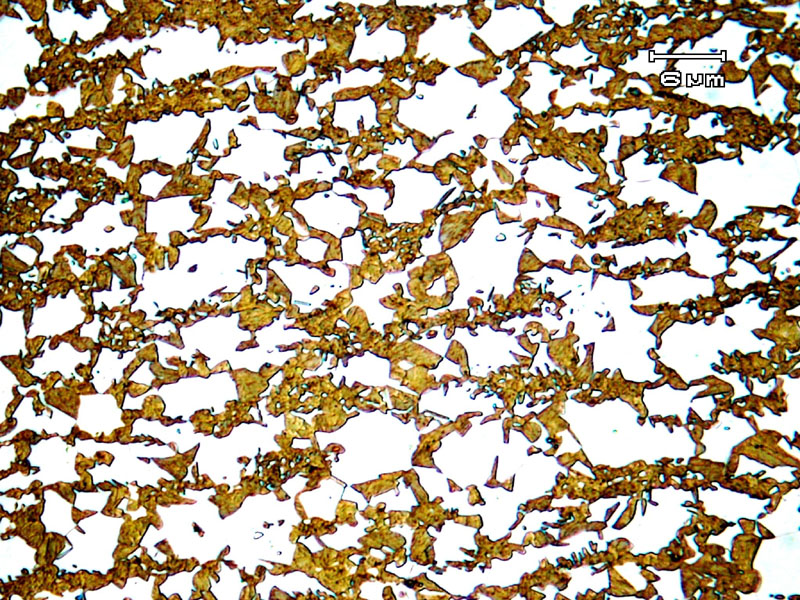

The following micrograph is from the DoIToMS Micrograph Library of the University of Cambridge. The actual micrograph was provided by Dr Amar K. De of ASPPRC, Metallurgical and Materials Engineering Department, Colorado School of Mines, of a dual-phase steel quenched from 800°C. The composition of the steels is Fe-0.15C-1.5Mn-1.5Si wt%. The white phase is ferrite and the remainder of the microstructure is a mixture of martensite and a small amount of retained austenite.

Some of the papers are reproduced here, with permission, from the Proceedings of Super-High Strength Steels, 2--4 November 2005, Rome, Italy, Associazione Italian di Metallurgica

The photographs of the gas containers were taken with permission at the OCAS Research Centre of ArcelorMittal, where this award winning application was invented.

| Superalloys | Titanium | Bainite | Martensite | Widmanstätten ferrite |

| Cast iron | Welding | Allotriomorphic ferrite | Movies | Slides |

| Neural Networks | Creep | Stainless Steels | Theses |

| PT Group Home | Materials Algorithms |

|

|