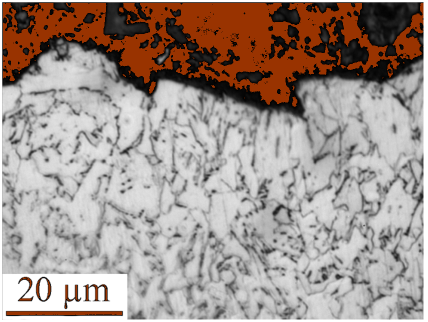

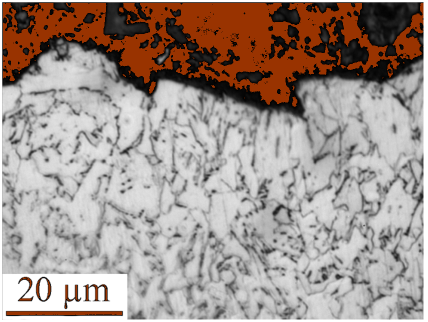

Large-diameter steel pipes are produced by induction seam-welding followed by induction-assisted heat treatment. The microstructure and distribution of crystal orientations have been studied and related to the mechanical properties of the welded regions. The welding and heat-treatment process leads to a microstructure, a simple observation of which can not explain the observed variations in toughness in the vicinity of the welding joint, because the crystallographic grain size, which represents the scale of similarly oriented adjacent grains, is much coarser than the ordinary grain size. Furthermore, heating the affected zone into the austenite phase field followed by cooling does not completely eliminate the coarse regions of similarly oriented grains. The consequences of this on mechanical properties are discussed.

Advanced Materials Research, Vols 89-91, 2010, 651-656.

Download high resolution images

| Synchrotron | Mathematical Models | Bake hardening | Nuclear | Irradiation |

| Residual stress | TRIP | 301L stainless | Hot-strength | Intervention |

| δ-TRIP | Metallography | Mechanicallly Alloyed | Topology | Retained Austenite |

| PT Group Home | Materials Algorithms |