Arrival in Sao Paulo

Spotted Professor Bob Cochrane (Leeds Universtiy) in the immigration queue

Sao Paulo airport

Sao Paulo airport

Sao Paulo airport

Sao Paulo airport

Waiting for the flight to Araxa

Checking in for Araxa

Steve Webster and Bob Cochrane

Shinohara from Nippon Steel

Nippon Steel and Sumitomo Metals are amalgamating to form one company

In the CBMM lounge in Sao Paulo, waiting for departure to Araxa

In the CBMM lounge in Sao Paulo, waiting for departure to Araxa

The plane for Araxa

A view from the plane

After landing at the airport in Araxa

After landing at the airport in Araxa

After landing at the airport in Araxa

After landing at the airport in Araxa

The hotel in Araxa - this is a spiral welded steel pipe

The hotel in Araxa

The hotel in Araxa

The hotel in Araxa

Courtesy of CBMM

The hotel in Araxa

The essence of Brazil

Sign in coach leading to the CBMM mine

At the mine.

A tree planting ceremony

Children of CBMM employees, greeting us

... with a lovely set of energetic songs

Professor Elena Pereloma helping to plant the tree

She is from Woolongong University in Australia

Bob Cochrane

John Speer from the Colorado School of Mines does his bit.

Ferroniobium

There is also a wildlife sanctuary at CBMM

Wolf

Giant ant eater

Exotic flora

The ore contains about 2 wt% or niobium in the form of pyrochlore (containign niobium pentoxide in the form (Ca,Na)2(Nb,Ta,Ti)2O6(OH,F)). It is first enriched by floatation and then heated in an electric arc furnace with aluminium and iron.

The aluminium reacts to liberate niobium which dissolves in the iron to produce ferroniobium

Here the slag (alumina rich) is being tapped.

We then visited the laboratories

This is the mine, which contains at least 200 years worth of reserves

The niobium mine.

The factory where the ore is processed is exceptionally clean.

The entire technology has been developed by CBMM

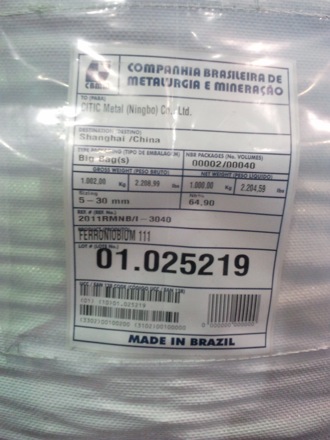

The final product

Here for shipment to China

Some of the pure niobium produced from niobium oxide is electron beam refined to extremely high purity.

Grain structures of the electron beam refined material

This is the electron beam melter

This is the electron beam melter

This is the electron beam melter

The conference

Here Malcolm Gray is being presented with a rare, niobium watch, in recognition of his services to CBMM.

David Delagostini Jarreta (on the left) and Daniel Pallos Fridman, both with CBMM