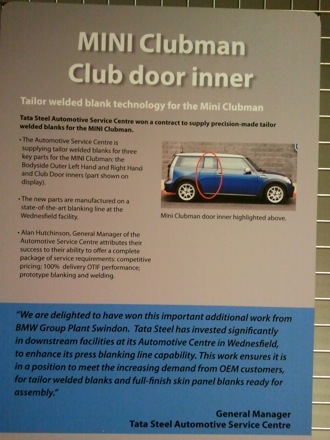

The bit identified on the mini is made from a tailored blank

The vertical line joins two different steels, which also differ in thickness. The blank is at the back, fabricated using laser welding, and the final component is in front.

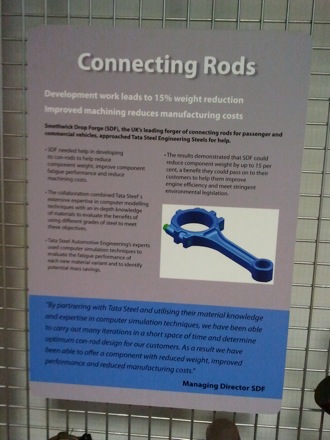

The process which leads to the manufacture of connecting rods, beginning with the blank at the top.

Two connecting rods in each forging

The final products before finish machining