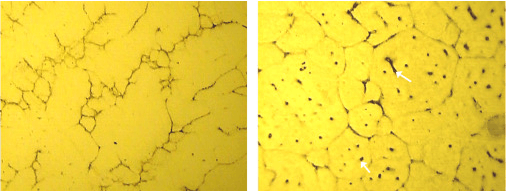

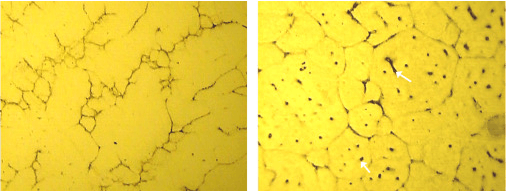

Super bainitic steel (0.74C, 1.64Si, 1.82Mn, 1Ni, 0.36Mo, 0.21Cr, 0.047Al wt%) after cold plastic deformation was used as the starting material for the bainitic treatment preceded by controlled cooling from the thixoforming temperature range. The Differential Scanning Calorimetry was used to determine the amount of the liquid phase fraction vs temperature in the solidus-liquidus range. The steel was heated up to 1430oC, which corresponded to about 30% of the liquid fraction. Then it was rapidly cooled in oil at three different temperatures: 240oC, 270oC and 300oC. The samples were then held at those temperatures for 5 h. The microstructure of the samples after treatment at 240oC showed globular grains (average size of 115 μm), containing carbide-free bainite as a mixture of ferrite plates with average thickness of 63 nm, and retained austenite plates of thickness 40 nm. Plates of martensite and blocks of austenite were visible in some grain. X-ray studies confirmed the presence of 20.1 % of austenite and 79.9% of ferrite with martensite. The sample revealed the highest compression strength of 6651 MPa, at yield strength of 1780 MPa and compression strain of 38%. With the increase of isothermal treatment temperature up to 270oC and 300oC, yield strength decreased to 1370 MPa, 1375 MPa and compression strength was 5243 MPa, 4138 MPa, respectively, while plastic strain reached 38.5% and 25 %, respectively. Higher temperature of bainitic treatment led to coarsening of super bainite plates and, in consequence to a decrease in mechanical properties. Initiation of crack propagation was observed at grains. They spread through the globules and eutectic, unlike in thixoformed tool steels, in which the crack path runs along the eutectic mixture between the globular grains. Preliminary studies of the corrosion resistance of Super Bainite steels containing carbide-free bainite structure were carried out. Results indicate slightly higher resistance in chlorides environment of the sample isothermally treated at 240oC/5 h preceded by controlled cooling from thixoforming temperature range than the sample treated in the conventional way (1000oC/15 min/240oC/20 h).

Materials Science and Engineering A 651 (2016) 708-719

| PT Group Home | Materials Algorithms |