|

| THERMOELECTRIC MATERIALS FOR THERMOCOUPLES |

TYPE K THERMOCOUPLE: BARE WIRE CONFIGURATIONType K thermocouple is a Ni base thermocouple introduced by Hoskins Manufacturing at the beginning of the 20th century: the positive and negative thermoelements were called Chromel and Alumel respectively. Table3 reports indicative compositions for Chromel and Alumel. Being Type K thermocouple defined according to the voltage versus temperature relationship, there is no need to use necessarily Chromel and Alumel compositions: other manufacturers produce positive (KP) and negative (KN) thermoelements with different compositions, which comply with the type K voltage versus temperature relationship.

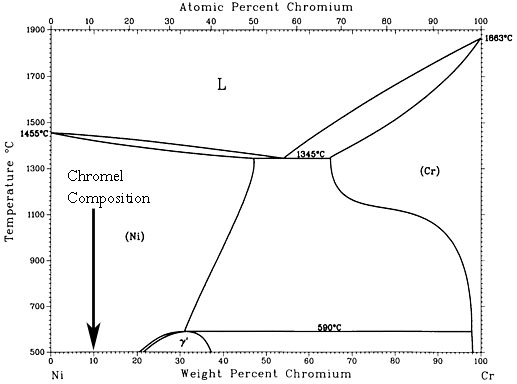

All the manufacturers of KP and KN alloys have selected compositions in order to have single phase alloys from ambient temperature to the solidus line: this prevents phase transformations along the thermoelements. Phase transformations in an alloy can produce changes in the existing phases and changes in their compositions: the Seebeck coefficient is dependent on composition and crystallography and for this reason single phase thermoelements are preferential choice. Figure13 is showing composition of Chromel on the Ni-Cr phase diagram.

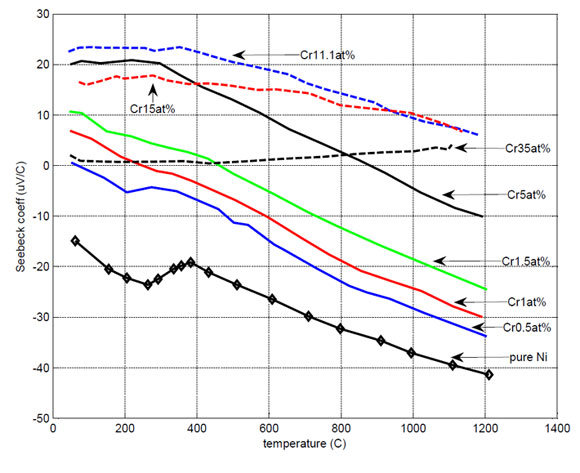

The composition of the type K thermoelements has been selected in order to have a thermocouple with high Seebeck coefficient: this may be achieved coupling a positive thermoelement with positive Seebeck coefficient with a negative thermoelement with negative Seebeck coefficient. Pure Ni has a negative Seebeck coefficient, but alloying Ni with other elements can result in an alloy with a positive Seebeck coefficient: this is the case of alloying Ni with Cr. Figure14 shows the effect of different Cr contents on the Seebeck coefficient of Ni: a maximum value for the Seebeck coefficient is obtained for Cr content of about 10at%, which matches the Chromel composition. The type K negative thermoelement is instead designed to contain about 5% of alloying elements selected to have a negative Seebeck coefficient over the whole temperature range.

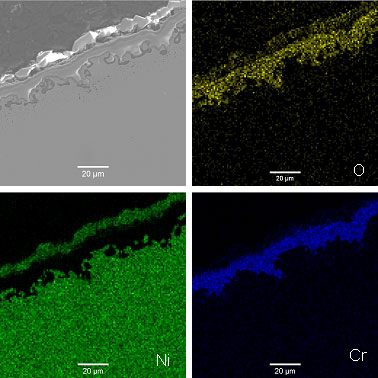

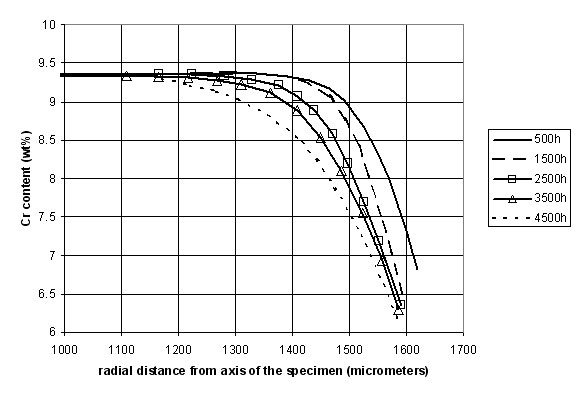

When type K bare wires thermoelements are exposed in air, oxidation takes place. Let us consider the effect of oxidation on the positive thermoelement: in a Ni-Cr alloy, Cr is oxidized preferentially forming Cr rich oxides. In Chromel the Cr content of the alloy is not enough to form a continuous external chromium oxide: an external Ni oxide is formed with an underlying Cr rich oxide layer. Figure15 shows the oxide layers formed after 110h at 1200°C. The content of Cr in the Cr oxide is higher than the Cr content of the alloy: a depletion of Cr from the base metal occurs in order to form Cr rich oxides and as a result the Cr content in the base metal and the Seebeck coefficient are lowered (see Figure14). Figure16 shows the Cr depletion in the base metal as a result of oxidation: the depletion affects deeper and deeper layers of base metal as the exposure time increases.

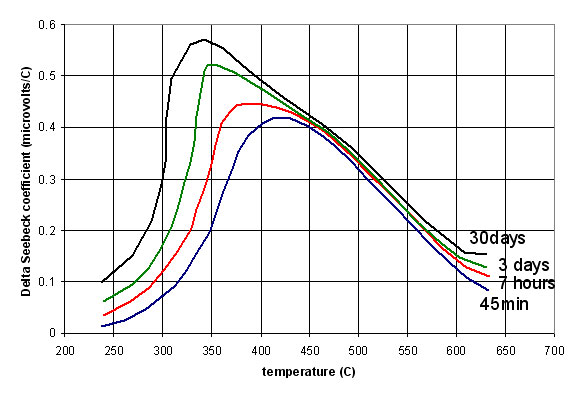

Chromel is affected by a short range order transformation occurring at temperatures between 200°C and 600°C; in this temperature range locally oredered atomic arrangements are developed, which produce an increase in the Seebeck coefficient, as shown in Figure17: the change is time dependent and at each temperature it increases with time till a maximum value. The change is maximum at about 400°C, while above this temperature it decreases. Above 600°C the positive thermoelement is completely disordered. When the junction of a type K thermocouple is exposed at temperature above 600°C, a portion of the positive thermoelement will undergo the short range order transformation and drift will take place.

References [1] ASM Handbook Volume 3 "Alloy phase diagrams" (1992) ASM International [2] M.V. Vedernikov, N.V. Kolomoets, Soviet Physics-Solid State 2 (1961) 2420 [3] N.A. Burley, "Solute depletion and thermo-E.M.F. drift in nickel-base thermocouple alloys". Journal of the [4] A.W. Fenton, "Errors in thermoelectric thermometers". Proceedings of the Institution of the Electrical

|

|||||||||||||||||||||||||||||||||||||||||||||

|

| Last update: August 31st 2009 © Michele Scervini 2009 |