It's a great pleasure to introduce the first of December's Papers of the Month, which has the highly unusual distinction of having one of our Part II students as first author, Sophie Mance, who completed the work for this paper during her summer internship at Helmholtz-Zentrum Hereon, Germany. Dr Domonkos Tolnai and colleagues hosted Sophie as part of the Department of Materials Science & Metallurgy's summer internship scheme, known as CaMPUS.

You can find out more about CaMPUS on our website. We are always pleased to hear from UK companies or academics in European universities/institutions who are interested in joining our internship scheme. Please contact teaching-office@msm.cam.ac.uk for more information.

James, Ruth and Jason (as joint Heads of Department)

**********************************************************************

Sustainability is an important consideration for manufacturers. One method of improving sustainability in the automotive and aerospace industries is improving fuel efficiency by using lightweight materials. Magnesium is a promising candidate for these applications — it is lightweight, has a high strength-to-weight ratio, and good machinability and castability. Alloying additions can further improve these properties as well as improving corrosion resistance and ductility. Metal-matrix composites (MMCs) using a Mg alloy matrix offer improved mechanical properties, whilst retaining Mg alloys’ light mass. Sustainability can also be considered when choosing a reinforcing addition. Recycled carbon fibres (rCFs) recovered from carbon-fibre-reinforced polymers maintain many of the mechanical properties of virgin CFs, but are cheaper and less energy intensive to produce. Finding uses for rCFs will also encourage more commercial recycling of carbon fibre reinforced composite materials. The aim of this study was to understand how the heat treatments and CF reinforcement affect twinning and slip in composite materials. These insights may then be used to develop high-performance composites as understanding the active deformation mechanisms during the compression enhance their design.

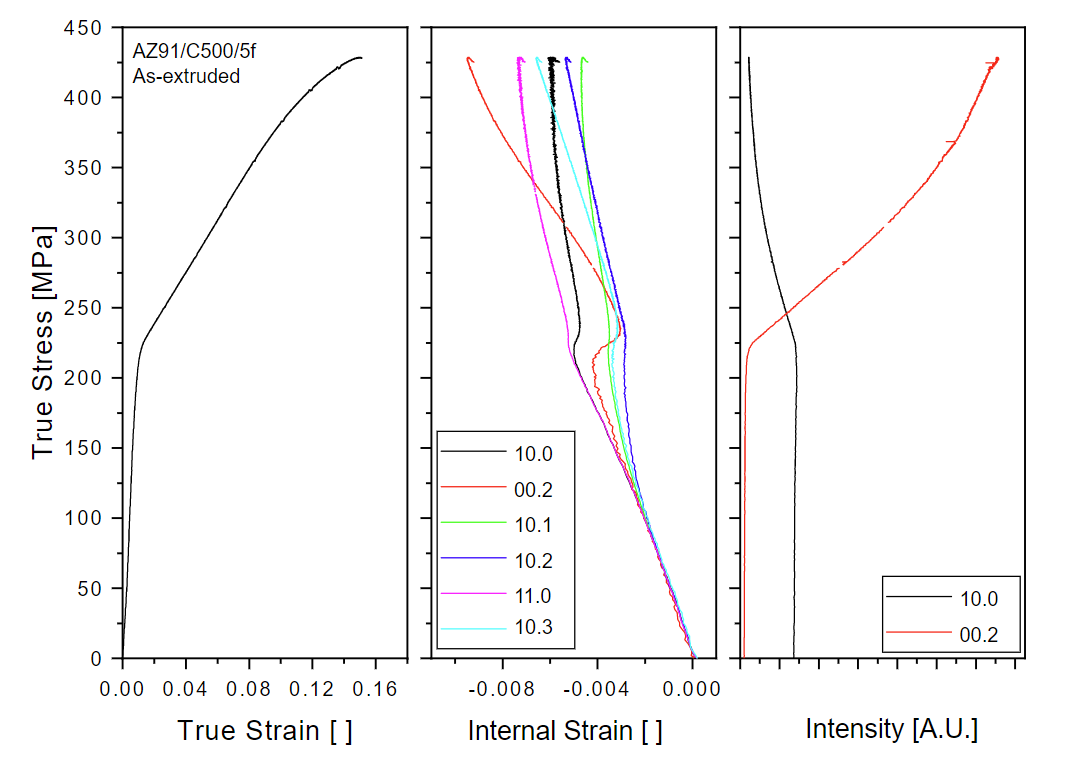

Figure caption: Macroscopic true strain (left), strain on lattice planes (centre), and intensity (right) against true stress for AZ91/C100/5f in as extruded state. The data from the in situ diffraction measurements is used to plot the strain on individual lattice planes. This provided information on the active deformation mechanisms, twinning is the dominant deformation for magnesium alloys in compression. The onset of twinning is seen in the right panel where there is a simultaneous increase in {00.2} intensity and a reduction in {00.1} intensity due to a lattice rotation. Heat treatment and the addition of reinforcing fibres can change the stress required for twinning and the ultimate compressive strength.

Sophie Mance, Hajo Dieringa, Jan Bohlen, Sarkis Gavras, Andreas Stark, Norbert Schell, João Pereira da Silva and Domonkos Tolnai, “In Situ Synchrotron Radiation Diffraction Study of Compression of AZ91 Composites Reinforced with Recycled Carbon Fibres”, Crystals, 12(11) 2022, 150