Hydrogen diffusion in iron is characterised by the large solubility and diffusivity differences between ferritic (BCC/BCT) and austenitic (FCC) phases – hydrogen has a much higher solubility and a much lower diffusivity in the latter. When austenite-containing steels are exposed to hydrogen-rich environments such as, cathodic polarisation in contact with water, H-containing gases, etc., austenite as acts both as an obstacle and a sink for hydrogen, slowing it down as it diffuses. The magnitude of this effect is closely linked to austenite shape but remains poorly understood, despite decades of research on H diffusion and embrittlement in steels and the important role retained austenite plays in it. In addition, the morphology of austenite is related to its mechanical stability – chunky austenite easily transforms into martensite under applied stress. This has implications for hydrogen embrittlement, as martensite is highly susceptible to early failure. Because of this, a better understanding of the morphology-diffusion-embrittlement relationship is needed to design hydrogen-resistant alloys.

In this paper, we tackle the role of austenite on H diffusion in multi-phase steels systematically for the first time, considering a range of factors such as morphology, interface kinetics and the additional effect of point traps using both experiments and modelling. This work follows the findings from Part I, where we showed that austenite as second phase cannot be parametrised and modelled as a point trap assuming local equilibrium with the surrounding ferrite. To solve this, we introduce a 2D hydrogen diffusion model accounting explicitly for the difference in diffusivities and solubilities between the phases and H interactions at the austenite/ferrite interfaces. We show that the rate of H absorption and the effective diffusivity in austenitic/ferritic steels are significantly lower when austenite islands are elongated and oriented normal to the diffusion direction, which is in line with classical experimental findings.

Our 2-part paper series demonstrates how informing diffusion models with experimental methods can be used to simulate the effect of austenite shape on hydrogen diffusion and how to separate it from the effect of other defects such as dislocations and grain boundaries. Our approach is not only applicable to steel but also to other alloys containing two or more phases with different H solubilities, such as titanium, zirconium and nickel alloys.

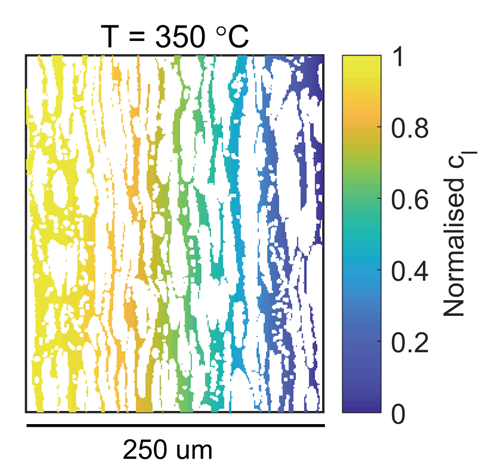

Figure: Snapshot at 350 oC of simulated H concentration map in ferrite surrounded by austenite islands (white regions) during thermal desorption spectroscopy. The microstructure corresponds to that of a duplex steel with 50% volume fraction of ferrite and austenite; H diffusion takes place from left to right of the image.

A. Turk, S. Pu, D. Bombač, P. E. J. Rivera-Díaz-del-Castillo, E. I. Galindo-Nava, "Quantification of hydrogen trapping in multiphase steels: Part II – Effect of austenite morphology", Acta Materialia 197 (2020) 253-268