High temperature superconductors (YBa2Cu3O7 and GdBa2Cu3O7) allow for passive and stable magnetic levitation when used in combination with rare-earth permanent magnets. This levitation has advantages for rotary magnetic bearings due to very low rotational loss and immunity to sudden failure which can occur in active magnetic bearings. Solid blocks of high temperature superconductor known as bulk HTS have previously successfully been used in the magnetic bearings of flywheel energy storage. However it has now been shown that high temperature superconducting tape which has a 1 micron superconducting layer can be used to create composite bulks also suitable for levitation despite containing less than 2% superconductor by volume. Superconducting tape (produced by SuperOx) was wound into 3 coils but without the ends electrically connected, to form cylinders. Axial levitation forces over 300 N were measured for 30 mm diameter permanent magnets placed inside the coils which is close to the maximum expected for ideal bulk cylinders. The currents induced inside the superconductor have been explained by detailed FEM modelling. The advantages of composite bulks made from superconducting tape include great flexibility over geometry, mechanical robustness and consistent superconducting properties. This work was supported by SKF.

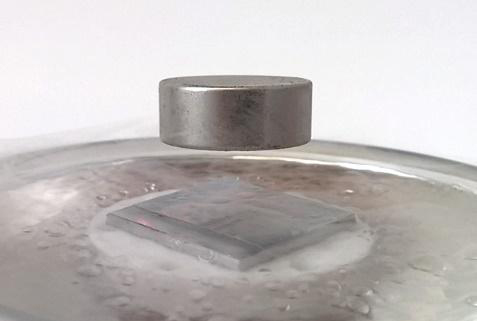

Figure: High-temperature superconducting tape can be arranged into soldered planar slab form as well as cylindrical form. Such stacks and slabs allow for the stable magnetic levitation of permanent magnets as demonstrated in the picture.

A. Patel, S.C. Hopkins, A. Baskys, V. Kalitka, A. Molodyk and B.A. Glowacki, “Magnetic levitation using high temperature superconducting pancake coils as composite bulk cylinders”, Superconductor Science and Technology, 28 115007 (2015).