Strain(work)-hardening is the main reason that alloys are significant structural materials. It ensures that flow is delocalized, imparts ductility and inhibits catastrophic mechanical failure. Metallic glasses (MGs) have desirably high yield stress and elastic strain limit, but they show strain-softening, leading to severe flow localization in shear bands and thereby to failure in tension without significant ductility. A collaboration between the IMR (Shenyang, China) and DMSM has now overturned the paradigm that MGs must strain-soften.

The generally accepted explanation of strain-hardening was given by G.I. Taylor in 1934: plastic flow involves the motion and proliferation of dislocations, and the hardening reflects increasing inhibition of their motion. In 1956, P.B. Hirsch’s group observed motion of dislocations. These firsts at Cambridge are now followed by work, which (after 85 years) reveals an entirely new type of strain-hardening in alloys ‒ accompanied by a fall in the energy of the sample, rather than a rise as in Taylor’s case.

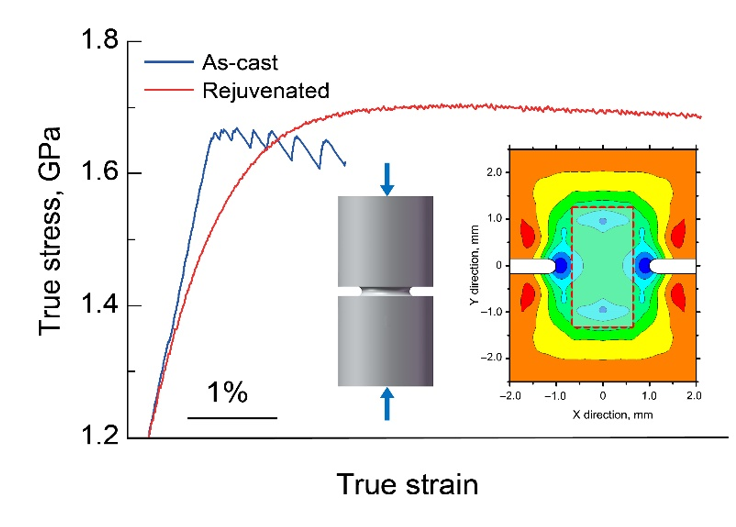

Figure caption: A notched cylinder of MG is compressed (blue arrows). In the central zone, small plastic strains occur under strong triaxial compression. These conditions induce a softening of the MG, shown in the coloured hardness map. A cylinder (dashed rectangle) is cut from the main sample and forms the test specimen for studies of the mechanical properties of what is now a ‘rejuvenated’ glass ‒ i.e. with raised energy. The stress-strain curves show the transformation in mechanical properties achieved when strain-softening and the consequent shear-banding are eliminated.

J Pan, YP Ivanov, WH Zhou, Y Li & AL Greer, “Strain-hardening and suppression of shear-banding in rejuvenated bulk metallic glass”, Nature 578 (2020) 559‒562.