Mike Ashby Associate Professor in Materials Science

MEng Imperial College London

PhD University of Cambridge

Multiscale Behaviour of Engineering Alloys

My research explores microstructure-property relationships at a range of length scales both in established and new engineering alloys. Through the discovery of the underlying science that governs alloy behaviour, my work aims to transform structural performance of materials through advances in our understanding of metallic material behaviour. I have a broad interest in ferrous and non-ferrous alloys used for various structural applications, spanning aerospace, automotive, defence, nuclear energy and healthcare sectors.

Micromechanics of Materials

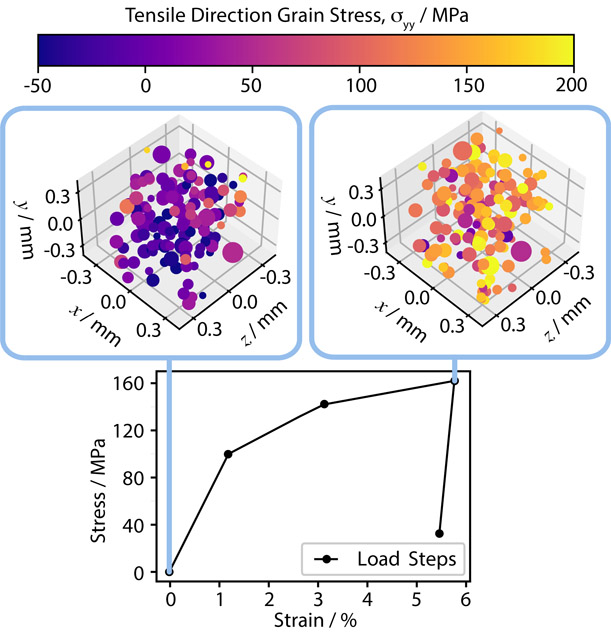

This work aims to relate macroscopic structural behaviour of materials to the controlling mechanisms, often at the sub-crystal scale. My research group has expertise in advanced experimental characterisation methods for quantifying deformation, but we also use various modelling methods (such discrete dislocation plasticity [DDP], crystal plasticity finite element method [CPFEM] and viscoplastic self-consistent [VPSC]) to guide our understanding. We have interest in dislocation behaviour, stress development and deformation-induced phase transformations both within and between grains. This includes crystallographic and chemical effects, especially in 3D, for simple and complex deformation sates.

Microstructure Development

The research group has interest in the evolution of microstructure in non-equilibrium conditions, particularly in the context of thermo-mechanical processing. This includes grain and precipitate development including phase transformations. We are interested in methods where new understanding can be incorporated into an alloy design process, aiming to exploit material behaviour by optimising mechanism-informed processing methods.

Advanced Diffraction Methods

We have interest in characterisation methods that offer high spatial, angular and/or temporal resolution to reveal mechanisms that control material properties. We offer expertise in developing experimental and data analysis methods for powder diffraction, 2D and 3D X-ray Diffraction (3DXRD), diffraction contrast tomography (DCT) and electron backscatter diffraction (EBSD). Our capability extends to using and developing dedicated testing environments for in-situ testing, focusing on microstructure and deformation behaviour.

-

J.A.D. Ball, J. Oddershede, C. Davis, C. Slater, M. Said, H. Vashishtha, S. Michalik, D.M. Collins. “Registration between DCT and EBSD datasets for multiphase microstructures” Materials Characterization 204 (2023) 113228. https://doi.org/10.1016/j.matchar.2023.113228

-

Y. Chen, Y.T. Tang, D.M. Collins, S.J. Clark, W. Ludwig, R. Rodriguez-Lamas, C. Detlefs, R.C. Reed, P.D. Lee, P.J. Withers, C. Yildirim “High-resolution 3D strain and orientation mapping within a grain of a directed energy deposition laser additively manufactured superalloy” Scripta Materialia 234 (2023) 115579. https://doi.org/10.1016/j.scriptamat.2023.115579

-

J.A.D. Ball, A. Kareer, O.V. Magdysyuk, S. Michalik, A. Vrettou, N. Parkes, T. Connolley, D.M. Collins “Implementing and evaluating far-field 3D X-ray diffraction at the I12 JEEP beamline, Diamond Light Source” Journal of Synchrotron Radiation 29 (4), 1043-1053 2022. https://doi.org/10.1107/S1600577522004088

-

D. Agius, A. Kareer, A. Al Mamun, C. Truman, D.M. Collins, M. Mostafavi, D. Knowles. “A crystal plasticity model that accounts for grain size effects and slip system interactions on the deformation of austenitic stainless steels” International Journal of Plasticity 152 (2022) 103249. https://doi.org/10.1016/j.ijplas.2022.103249

-

D.M. Collins, N D’Souza, C Panwisawas, C Papadaki, GD West, A Kostka, P. Kontis. “Spinodal decomposition versus classical γ′ nucleation in a nickel-base superalloy powder: An in-situ neutron diffraction and atomic-scale analysis” Acta Materialia 200 (2020) 959-970. https://doi.org/10.1016/j.actamat.2020.09.055

-

D.M. Collins, M. Mostafavi, R.I. Todd, T. Connolley, A.J. Wilkinson. “A synchrotron X-ray diffraction study of in situ biaxial deformation” Acta Materialia 90 (2015) 46-58. https://doi.org/10.1016/j.actamat.2015.02.00