Ductile-brittle transition temperature

Most metals undergo a transition from brittle to ductile behaviour as temperature increases. When temperature is low, the temperature dependent dislocation movement is inhibited, making metallic materials more susceptible to brittle fracture.

The ductile-brittle transition temperature can be found by examining the material for a range of temperatures using the Charpy impact test. This involves impacting the sample with a pendulum with mass, \( m \) from the original height \( h_{\rm{i}} \) and measuring the recovery height \( h_{\rm{f}} \). The impact energy, \( U \) is

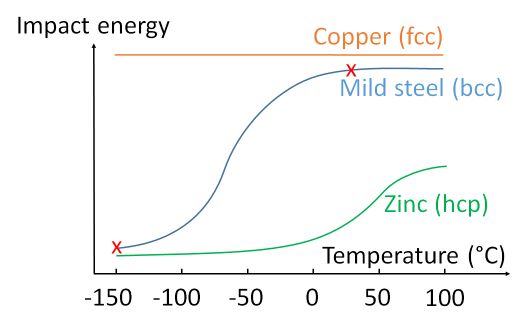

\[ U = mg\left( {{h_{\rm{i}}} - {h_{\rm{f}}}} \right) \]This impact energy indicates the toughness of the material at a specific temperature. In a plot of impact energy against temperature, the temperature where there is a dramatic increase in impact energy is the ductile-brittle transition temperature.

Figure 16. Instrument for Charpy impact test

Figure 17. Variation in impact energy with temperature (red crosses indicate the samples tested in Figure 18.

hcp metals like zinc, have limited slip systems, so they remain brittle at room temperature. In contrast, fcc metals have a very low energy barrier for plastic flow, so do not usually show any ductile brittle transition in this temperature range. However, bcc metals, such as mild steel, become brittle at low temperatures. The ductile brittle transition can be shown by cooling mild steel in liquid nitrogen: samples tested at room temperature deform and absorb much more energy than samples tested at liquid nitrogen temperature.

Figure 18. Mild steel under Charpy impact test (top sample tested at room temperature; bottom two cooled in liquid nitrogen)

The ductile brittle transition can be encountered in the polar regions, where a temperature close to the ductile-brittle transition can be achieved. This behaviour was first identified by Constance Tipper of the Engineering Department in Cambridge, when studying the failure mechanism of the Liberty Ships during the Second World War.

Figure 19: USS Ponaganset (AO-86), at the General Ship and Iron Works, Boston, MA., 9 December 1947, shortly after breaking in half during reactivation. (from Wikimedia Commons)