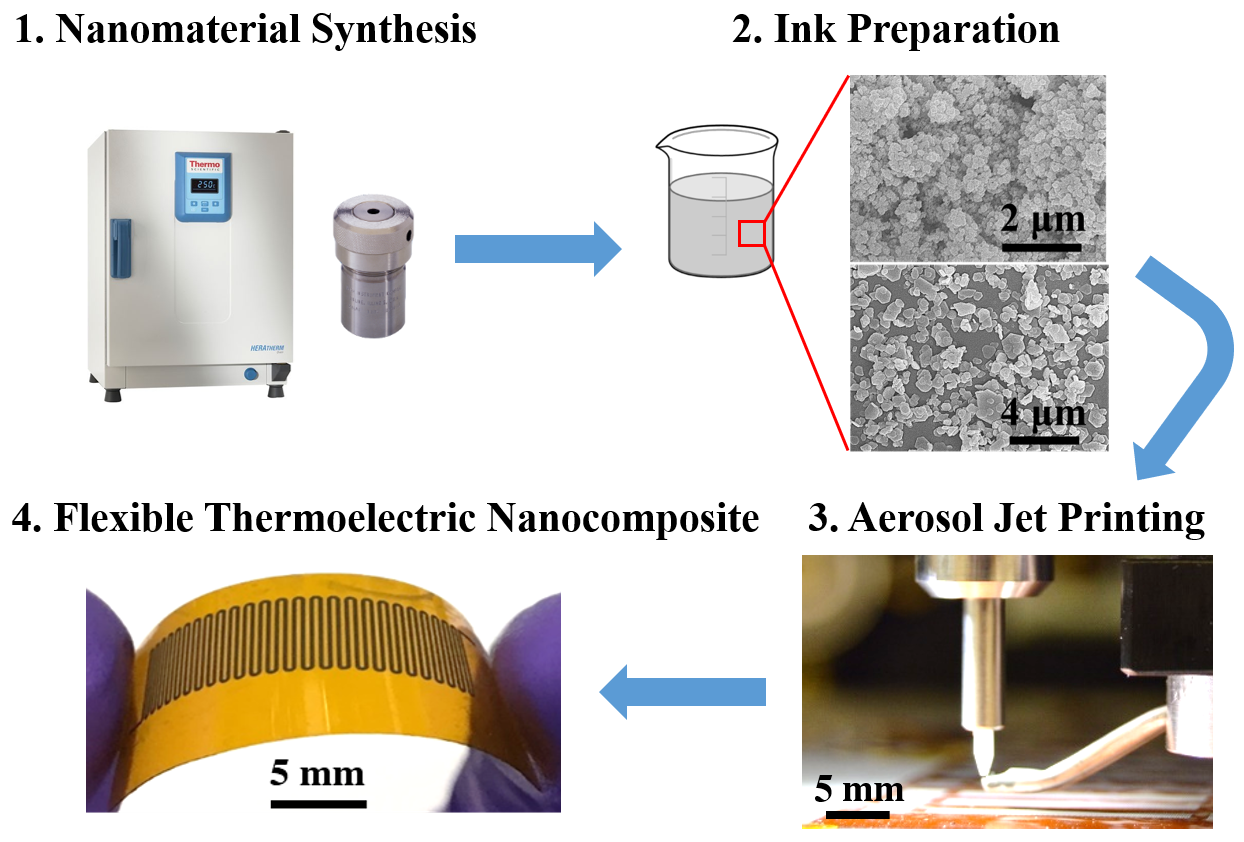

Thermoelectric materials, capable of interconverting heat and electricity, are attractive for applications in thermal energy harvesting as a means to power wireless sensors, wearable devices and portable electronics. However, traditional inorganic thermoelectric materials pose significant challenges due to high cost, toxicity, scarcity, as well as brittleness particularly when it comes to applications requiring flexibility. On the other hand, organic thermoelectric materials are particularly well suited for potentially low-cost and flexible thermoelectric applications, but their thermoelectric performance still lags behind their inorganic counterparts. In this work, hybrid thermoelectric nanocomposites have been developed from bespoke inks printed onto flexible substrates, and their performance evaluated as a function of composition, as well as upon repeated flexing. We show that a specially designed in-situ aerosol mixing method ensures uniform distribution of Bi2Te3/Sb2Te3 nanocrystals, within a poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) matrix during the printing process. The printed nanocomposites were found to have good thermoelectric performance even upon repeated flexing, making these hybrid materials particularly suitable for flexible thermoelectric applications.

Figure: Hybrid thermoelectric nanocomposites have been developed from bespoke inks printed onto flexible substrates, and their performance evaluated as a function of composition as well as upon repeated bending.

C. Ou, A. Sangle, A. Datta, Q. Jing, T. Busolo, T. Chalklen, V. Narayan & S. Kar-Narayan, “Fully Printed Organic-Inorganic Nanocomposites for Flexible Thermoelectric Applications”, ACS Applied Materials & Interfaces (2018)