Battery Materials

Fundamental and applied research projects that can address and achieve real improvements in battery life, safety, energy & power density, reliability and recyclability of advanced batteries, supercapacitors and fuel cell type of batteries are undertaken by Departmental researchers. Topics of research of specific interest are:

- Nanostructured carbon and silicon anodes for Li-ion batteries

- Solid electrolyte and sensors for safe batteries

- Lightweight batteries

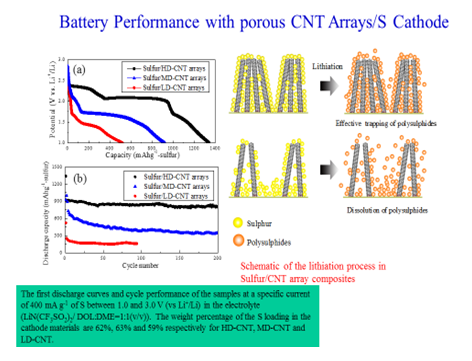

- Special chemical layers for sulphur cathodes in Li-S batteries

- Recycling and recovery of components from spent batteries

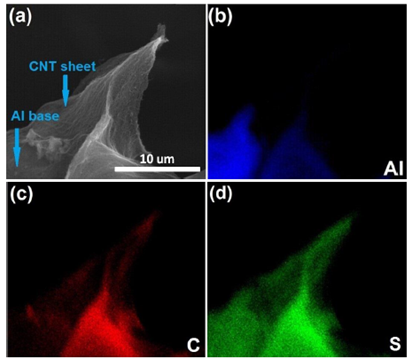

- Advanced electron microscopy characterization of battery components

- In situ imaging and electrochemical characterization of batteries

In particular researchers have advanced the use of nano-carbon scaffolds infiltrated with sulphur and absorbing interlayers in order to fabricate new Li-S batteries with energy densities that are 100% higher than the best Li-ion batteries with improved cycle-life, thus potentially overcoming an outstanding problem that has hampered progress for several decades. This project received various innovation awards including Dow Sustainability Innovation Grand Award in 2013.

Figure caption: Chemical mapping of the sulphur loaded CNT arrays. (a) SEM image (b) aluminium signal corresponding to the substrate, (c) carbon and (d) sulphur EDX maps.

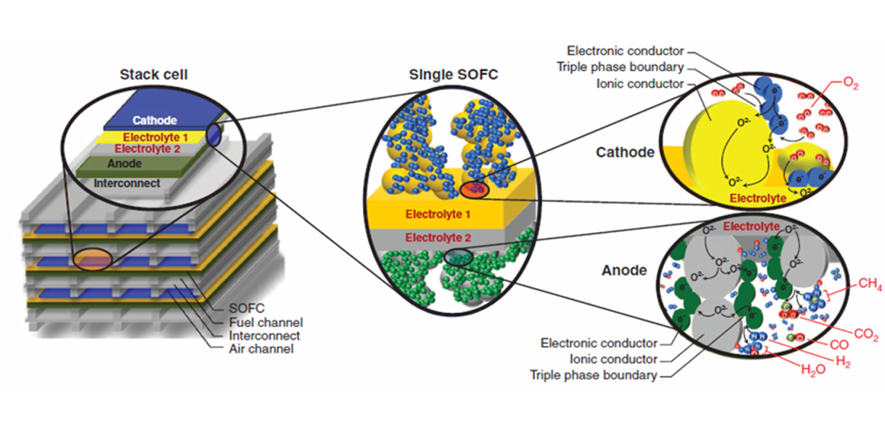

Fuel Cells

State-of-the-art SOFCs operate at high temperature > 800oC, requiring expensive but fragile materials and vulnerable sealing methods. CAPEX is very high and OPEX may be very high due to materials stress in operation. Attempts in marginally decreasing temperature, is only marginally helpful but the fundamental issues remain. At temperatures below 620oC, frugal metallic materials and robust sealing techniques can be used, that can guarantee long life and low maintenance issues. As the temperature is decreased, the active fuel cell components must be made very thin using low-cost technologies. At Cambridge we have an edge by focussing on fabricating fuel cell components by InkJet printing and infiltrating the active layers with catalysts to achieve the performance demand. We have developed substantial know-hows in this technological capability. At low temperatures enhanced activation of reactions at both electrodes become critical. Selection of suitable catalysts in appropriate morphology is being developed.