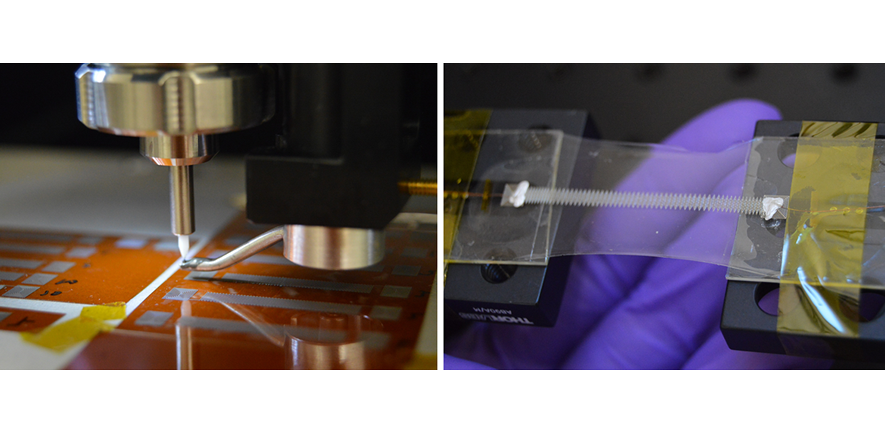

Banner image: Left panel - Aerosol jet printing of large-area, fine-feature electronic devices on flexible substrates. Right panel - Fully printed and stretchable strain sensor.

Research in the Department focuses on the development of novel sensor materials and devices using a variety of inputs for diverse applications including environmental and safety monitoring, diagnostics and wearable electronics.

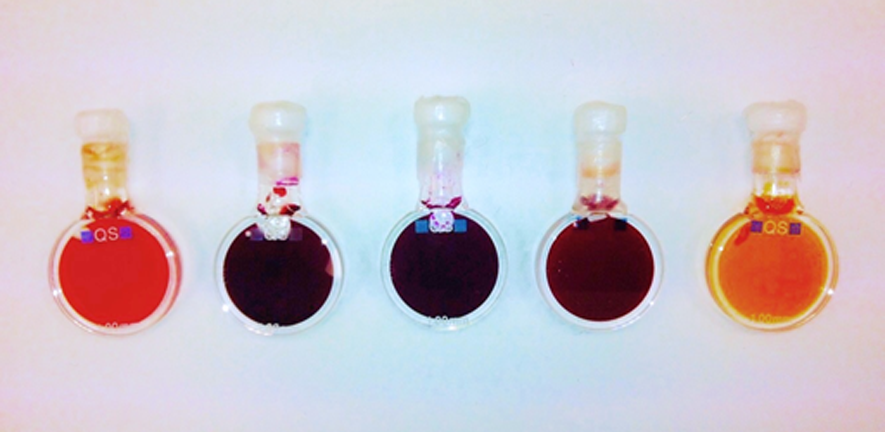

Optical sensor platforms exploit the quantitative change in the signal of photoluminescent molecules or polymers in response to a change in the local chemical or biological environment. This response may manifest itself as a decrease in the emission intensity or a change in the colour. Optical sensors are currently being developed for biodiagnostics (e.g. to monitor changes in cell membranes) and chemical analyte detection (e.g. gases, small molecules).

Figure caption: Colorimetric polymer sensor for surfactants

Figure caption: Colorimetric polymer sensor for surfactants

Another area of interest includes the development of solid-state sensors for gas monitoring, some of which are now commercialised products for application in quality and process control, automation, environmental and safety monitoring. Recent research has focused on the design of nanostructured solid oxide single chips using MEMS processing. These chips are able to selectively detect different gases based on their inherent physical and chemical properties, even for molecules of the same or similar molecular weight.

Another area of interest includes the development of solid-state sensors for gas monitoring, some of which are now commercialised products for application in quality and process control, automation, environmental and safety monitoring. Recent research has focused on the design of nanostructured solid oxide single chips using MEMS processing. These chips are able to selectively detect different gases based on their inherent physical and chemical properties, even for molecules of the same or similar molecular weight.

Figure caption: Sensors for Safety Monitoring in industrial environment by S4H Ltd, Nagpur

Sensors based on bio-compatible piezoelectric polymeric nanomaterials are being developed for applications in bio-medicine, for example as self-powered temperature and/or blood pressure sensors. Research is also being carried out on triboelectric nanomaterials for application in novel self-powered position and/or strain sensors, and for applications in wearable devices. In most cases, the sensors are fully printed, flexible and stretchable, fabricated using nano-particulate inks of functional materials via advanced large-area, fine-feature printing techniques.

Accurate temperature control is essential for safe and efficient operation in aerospace, power generation, metal and ceramic processing and manufacturing. But these are also some of the most challenging environments in terms of temperature and chemical degradation. We research the degradation occurring during the lifetime of thermocouples and are developing novel Ni-based thermocouples which operate at higher temperatures and with reduced thermal drift, including a patented dual-walled thermocouple recently licenced through Cambridge Enterprise to TE Wire and cable LLC.

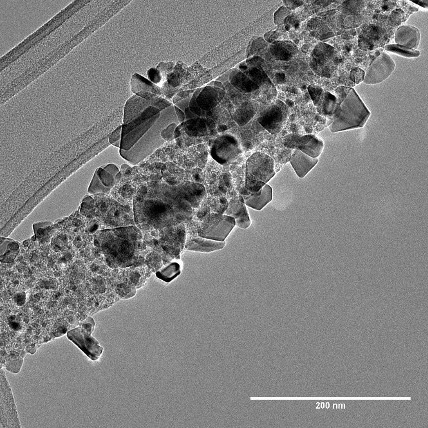

Figure caption: A transmission electron micrograph of elastically flexible ceramic material (up to 90 wt % weight) on nano structured carbon backbone (10 wt %) for new applications in ultra-small sensors, flexible energy devices and energy harvesters.