Physical metallurgy is the study of the physical properties of metals and alloys in their most broad sense. It covers areas such as the crystal structures of metals and alloys, their elastic and plastic properties, precipitation hardening, phase stability and phase transformations, creep, fracture, fatigue, solidification and powder processing.

Plasticity, the study of the behaviour of metals and alloys beyond their elastic limit is relevant to the processing of metals and alloys from solid ingots through to industrial components. An understanding of physical metallurgy is central to the development of new steels, improved nickel-base alloys for turbine blades for the aerospace industry and the processing of titanium alloys used as fan blades in aircraft engines.

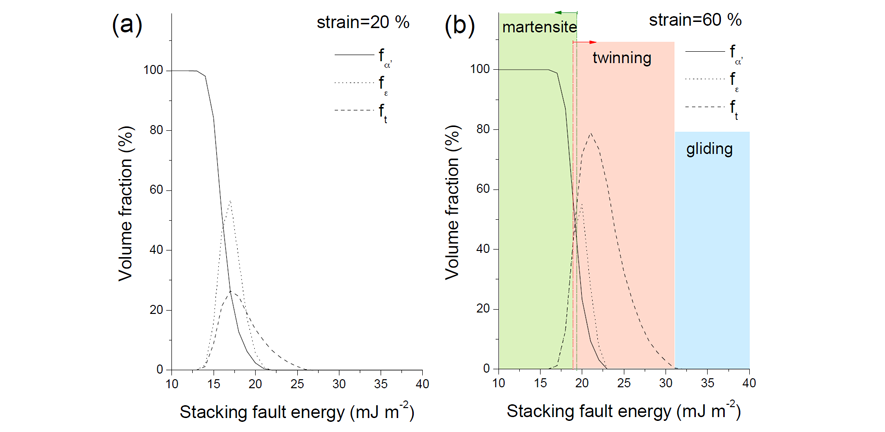

Novel modelling and characterisation techniques are employed to study the fundamentals of plasticity, deformation-induced phase transitions, and mechanical properties of advanced alloys. For instance, the figure above shows maps with the operation range of α’-martensite, ε-martensite and twinning in austenitic (TRIP/TWIP) steels at different strains and stacking fault energies. The maps have been built by introducing a unified approach to predict these structures in terms of the applied stress and steels’ chemical composition.