Battery Recycling:

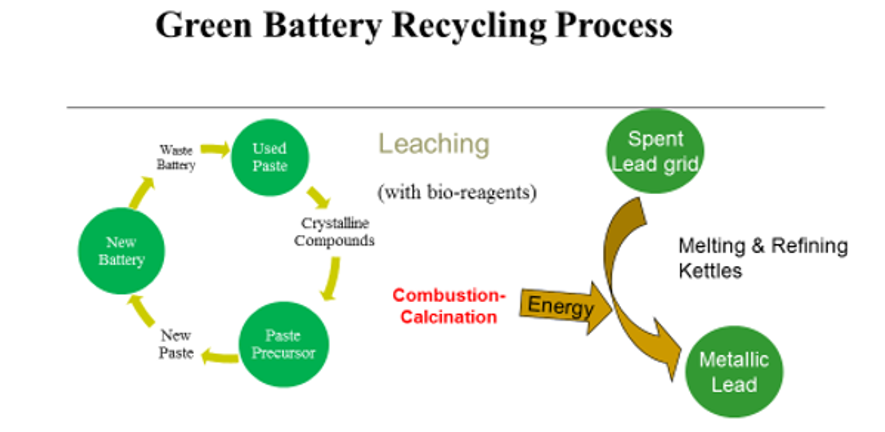

Dr Kumar, and his research team have developed in the laboratory a new environmentally clean-process for recovering electro-active paste material from automotive- and off-grid renewables storage batteries for making new batteries (paste-to-paste recovery). Several other research centres and universities have followed this lead by setting up collaborative research with Cambridge. A technological-plan based on this work was given the first Armourers & Brasiers Venture Prize in 2008, followed by global industrial interest via Cambridge Enterprise. Several companies, research centres and universities have evaluated the technical feasibility of the process. Based upon a number of successful technical and financial evaluations by the industry, Aurelius Environmental Ltd. have licensed the technology from the University of Cambridge and have set up a pilot-plant near Birmingham, UK with a view to globalize access to this technology.

Dr Kumar has published over 25 papers in journals and over 10 talks in conferences and workshops in this subject alone in the past 8 years. Dr Kumar has supervised around 10 PhD, post-doctoral and visiting researchers in this area.

Waste as Reagents:

Based upon academic research and laboratory demonstration, Dr Kumar has put forward a method for using steel industry waste dust as a reagent for refining liquid iron, currently done using relatively very expensive magnesium. Initial research work led to collaboration and successful plant trials with the steel industry in the UK and in Tanshang Iron and Steel, China and currently, Dr Kumar as a technical consultant, is participating on collaborative full scale plant trials taking place in Slovakia between University of Cambridge, Carmeuse and US Steel.