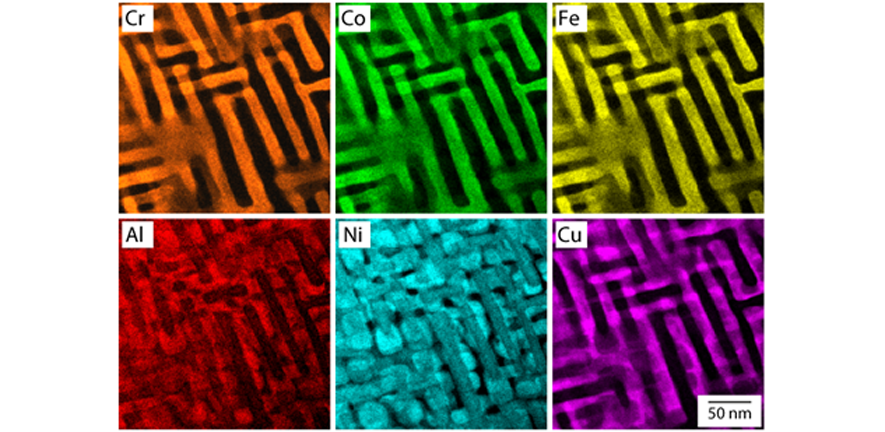

Banner image: Elemental composition maps of an Al0.5CrFeCoNiCu High Entropy Alloy showing a spinodally-decomposed structure with an L12 phase (www.sciencedirect.com/science/article/pii/S0921509315302586)

The limiting factor for many engineered components is the capability of the alloys from which they are fabricated. Consequently, there is a continual demand to improve existing alloys, as well as to design new ones, in order to meet the demands of future applications. An alloy’s properties depend on its chemical composition, how these atoms are arranged and the larger scale features that make up the microstructure. Within the department, we characterise and model the structures of alloys across a wide range of length scales, from the atomic level to component scale. The fundamental understanding of alloy behaviour we obtain enables us to enhance existing materials and develop new alloy concepts.

Microstructural Characterisation

The advanced characterisation techniques available within the Department enable our researchers to thoroughly investigate the structure of a material, and the distribution of different elemental species within it. Through the use of the state-of-the-art electron microscopy facilities, alloy microstructures can be examined down to the atomic columns that make up their crystals and subtle changes in elemental distributions, which may only exist for a few atomic layers, can be revealed. In addition, through the use of international radiation facilities, such as the Diamond Light Source and ISIS Neutron and Muon Source in Oxfordshire, our scientists are gathering data and developing new analytical techniques that enable them to identify and quantify the presence of atomic clustering.

Exploring new alloy concepts

Research in the department is exploring several new material concepts to address a range of industrial opportunities. These materials include High Entropy Alloys, Refractory Metal-based alloys as well as novel Ni- and Co- based superalloys. The approach combines empirical relationships and first principal calculations, as well as neural networks and the knowledge gained through alloy characterisation work to identify promising candidate materials prior to evaluation through rapid small-scale prototyping.