Professor of Superalloys

MA University of Oxford

PhD University of Oxford

Mechanical Properties and Microstructure

Over the last 50 years turbine entry temperatures (TETs) have risen from 800ºC to 1600ºC. Materials developments in all turbine components, are critical to achieving this, but engine designers are looking for a TET of 1800ºC to increase engine efficiency and reduce environmental impact. We focus on understanding the fundamental mechanisms determining the mechanical properties of turbine materials and use this to produce tools and strategies for materials development and life prediction.

Alloy development of fourth-generation single-crystal alloys

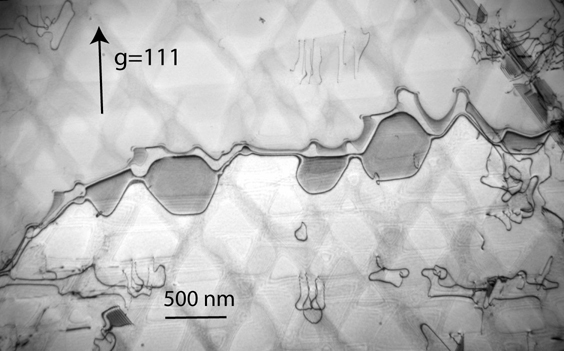

Nickel-base single-crystal superalloys can be strengthened by the addition of tungsten and rhenium, but doing so while maintaining reasonable density, stability and environmental resistance requires careful optimization of the composition and microstructure. Our work is aimed at understanding the mechanical properties at all temperatures experienced in service and involves creep LCF and TMF testing, combined with TEM and SEM of the deformed microstructures. In fourth-generation patented alloys developed at Cambridge, the role of ruthenium in stabilising and strengthening the alloys is being investigated. As part of the 'Alloys by Design' project, the interactions of dislocations with the γ' precipitates are being modelled using phase-field techniques.

Oxidation and coatings

Thermal-barrier coatings are an integral part of component design: understanding both the oxidation kinetics of nickel-based alloys and their long-term interaction with various coating systems is vital to component lifing and future design strategies. Projects involve the time-dependent oxidation behaviour and oxide morphology, and the compatibility of various coatings with both commercial and experimental nickel-base superalloys. New methodologies, developed in Cambridge, have been adopted by Rolls-Royce as part of their worldwide component lifing strategy.

| Nickel-based superalloy TMS82 during the early stages of primary creep showing andislocation ribbon passing through both precipitates and matrix |  |

- RA Hobbs, S Tin & CMF Rae, "A castability model based on elemental solid-liquid partitioning in advanced nickel-base single-crystal superalloys"Metall. Trans. A 36A, 2761-2773 (2005).

- CMF Rae, MS Hook & RC Reed, "On the precipitation of topological close packed phases at aluminide coatings on superalloys and the effect of precipitate morphology" Mater. Sci. Eng. A 396, 231-239 (2005).

- CMF Rae & RC Reed, "Primary creep in single crystal superalloys: Origins, mechanisms and effects" Acta Mater. 55, 1067-1081 (2007).