Under the microscope, multi-phase steels containing martensite are a mess full of defects and secondary phases - this makes them very strong but often not very ductile. They are also made brittle by hydrogen, which ends up in metal components in all sorts of ways, such as during electroplating, in cathodically polarised gas pipes, in steam vessels and hydrogen storage tanks and even in primary metallurgy where moisture in the feedstock dissociates into hydrogen, causing cracking in large castings. Component heat treatment -or hydrogen bake-out- must then take place but this process can be quite long and also detrimental for mechanical properties. This means that the use of martensitic steels needs to be carefully weighed against the risk of hydrogen embrittlement and the potential for catastrophic failure or the complications associated to a bake-out treatment. Predictive models for hydrogen diffusion exist, but have lacked accurate parameters of hydrogen interactions with the various defects in martensite. These defects, such as carbide interfaces and dislocations, attract hydrogen and slow it down, i.e. they act as H traps, but exactly by how much was hard to predict, because of the number of different types of defects.

In this paper, we quantify systematically the H trap density in martensite resulting from the presence of dislocations, grain boundaries and retained austenite (second phase) through a combination of correlative characterisation, hydrogen permeation, thermal desorption and diffusion modelling. The result is a set of equations relating H segregation to defect density allowing for the first time to deconvolve key microstructural constituents affecting H diffusion in martensite. Our results also show that retained austenite cannot be effectively modelled as a point trap under the assumption of local thermodynamic equilibrium, which is frequently used to model its effect on H diffusion, and that bulk trapping must be considered at least in two dimensions, which is addressed in Part II of this series. This work enables better modelling of hydrogen diffusion and embrittlement on a component level and contributes to emerging applications such as hydrogen storage and infrastructure.

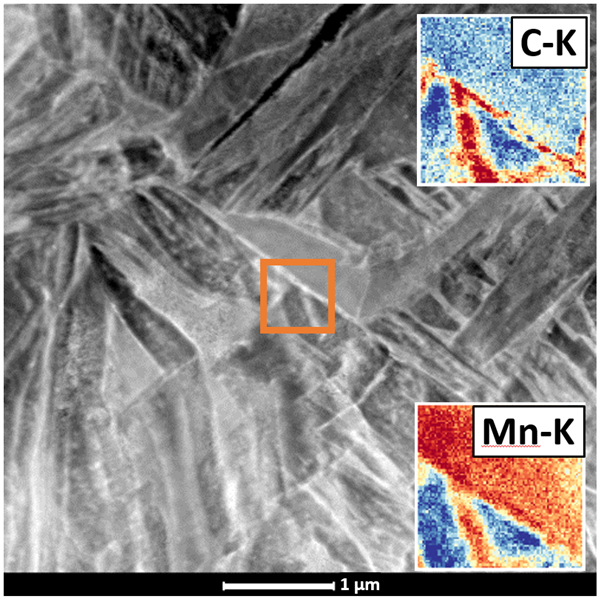

Figure: HAADF STEM/EDX image inside high-angle boundaries in martensite showing numerous laths and very fine retained austenite, all acting as H traps. The insets are the denoised signals of C and Mn which are associated to retained austenite.

A. Turk, G.R. Joshi, M. Gintalas, M. Callisti, P.E.J. Rivera-Díaz-del-Castillo, E.I. Galindo-Nava, "Quantification of hydrogen trapping in multiphase steels: Part I - Point traps in martensite", Acta Materialia 194 (2020) 118-133