In order to prevent wear, the performance of bearing oils is augmented by special chemicals referred to as anti-wear (AW) additives. Their function is to develop a thin sacrificial protective layer known as tribofilm, a product of chemical reactions triggered by tribological conditions. At the microscale, tribofilms developed by some AW additives are well known to cover the surface of the material with an uneven layer of patch-like morphology. This is detrimental to performance, as certain regions of the material are often left bare without any protective film. This also leads to increased surface roughness and, as a result, higher friction, which is undesired.

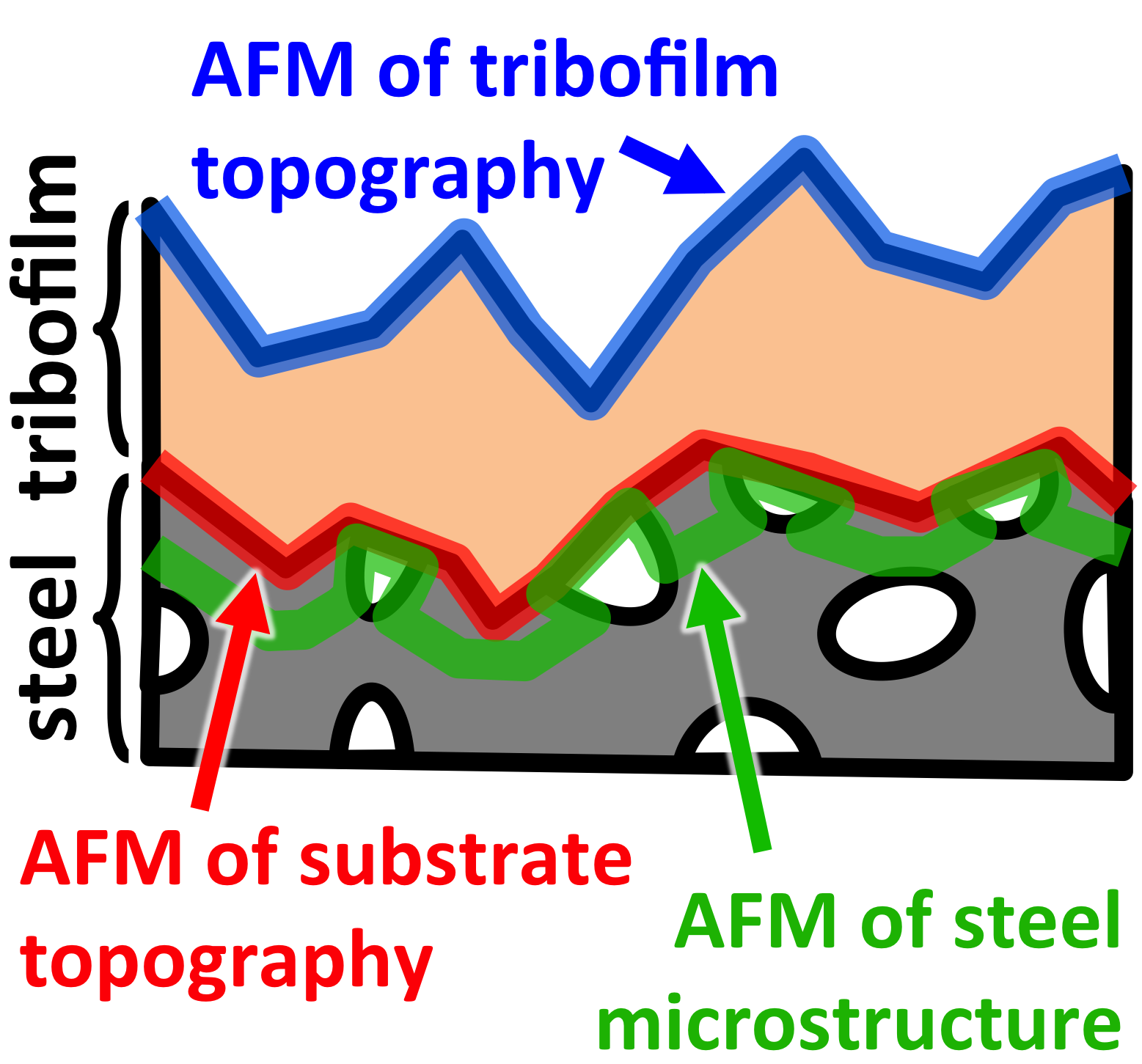

To investigate the structure of the tribofilm and its relation with the microstructure, a new atomic force microscopy (AFM) technique was developed. AFM topography micrographs of the same region were obtained before applying EDTA (ethylenediaminetetraacetic acid) to remove the tribofilm, after applying EDTA, and subsequently after etching; this unveils the microstructure of the underlying steel. By overlaying the three micrographs the new technique has allowed, for the first time, to establish the correspondence between the microstructure of bearing steels, the morphology of the tribofilm and bearing performance.

J. J. Rydel, R. H. Vegter, and P.E.J. Rivera-Diaz-del-Castillo, "Tribochemistry of bearing steels: A new AFM method to study the material–tribofilm correlation", Tribology International, 98 (2016) pp. 74–81