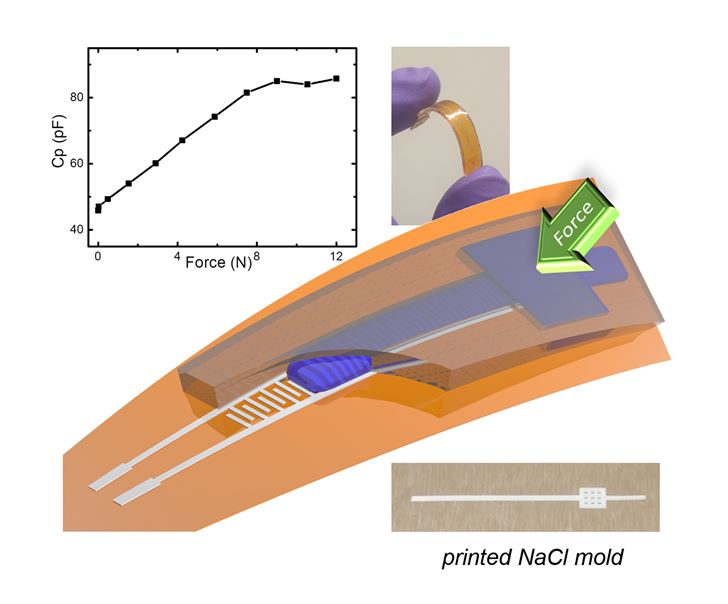

Force sensors that are thin, low-cost, flexible, and compatible with commercial microelectronic chips are of great interest for use in biomedical sensing, precision surgery, and robotics. By leveraging a combination of microfluidics and capacitive sensing, we have developed a thin, flexible force sensor that is conformable and robust. The sensor consists of a partially filled microfluidic channel made from a deformable material, with the channel overlaying a series of interdigitated electrodes coated with a thin, insulating polymer layer. When a force is applied to the microfluidic channel reservoir, the fluid is displaced along the channel over the electrodes, thus inducing a capacitance change proportional to the applied force. The microfluidic molds themselves are made of low-cost sacrificial materials deposited via aerosol-jet printing, which is also used to print the electrode layer. We envisage a large range of industrial and biomedical applications for this force sensor, and have been developing these for use in sensor-assisted orthopaedic surgery. A patent application has been filed, and the technology forms the basis of a new spinout company from the department, ArtioSense Ltd.

Figure: Highly flexible, capacitive force sensors based on microfluidics. The sensors exhibit a linear capacitance response to applied force. Their design can be easily tuned to achieve a range of sensitivities and force measurements via aerosol-jet printing, which is a microscale additive manufacturing technique capable of rapid prototyping.

Q Jing, A Pace, L Ives, A Husmann, N Ćatić, V Khanduja, J Cama, and S Kar-Narayan, "Aerosol-Jet Printed Conformable Microfluidic Force Sensors", Cell Reports Physical Science 2 100386 (2021).