The interior of the combustion zone of a standard jet engine in a commercial aircraft is an exceptionally hostile environment where engine materials experience extremely high temperatures (beyond 1000°C), rotational stresses, and intense oxidation for extended periods of time. Only high-performance materials, such as nickel (Ni)-based superalloys, can be used in these parts of the engine due to their excellent strength and oxidation resistance at high temperatures. However, existing superalloys are already operating at their maximum temperature limits. To withstand the harsher temperature and oxidation conditions required for more efficient engines, next-generation Ni-based superalloys with superior oxidation resistance must be developed.

It is generally accepted that the Ni-based superalloys with the best oxidation resistance at high temperatures typically rely on the rapid formation of a continuous surface layer of alumina (Al2O3) that prevents further oxidation damage. However, the formation of a continuous layer of alumina can be challenging since the chemical kinetics at typical service temperatures tend to favour the formation of a less-protective layer of chromia (Cr2O3) in these materials. Researchers at the Rolls-Royce University Technology Centre have devised a method that uses a pre-oxidation treatment to promote the formation of a protective layer of alumina for dramatically reduced oxidation damage. The findings could ultimately be used to assist in the development of next-generation polycrystalline Ni-based superalloys for enhanced oxidation resistance, leading to more fuel-efficient and sustainable aviation.

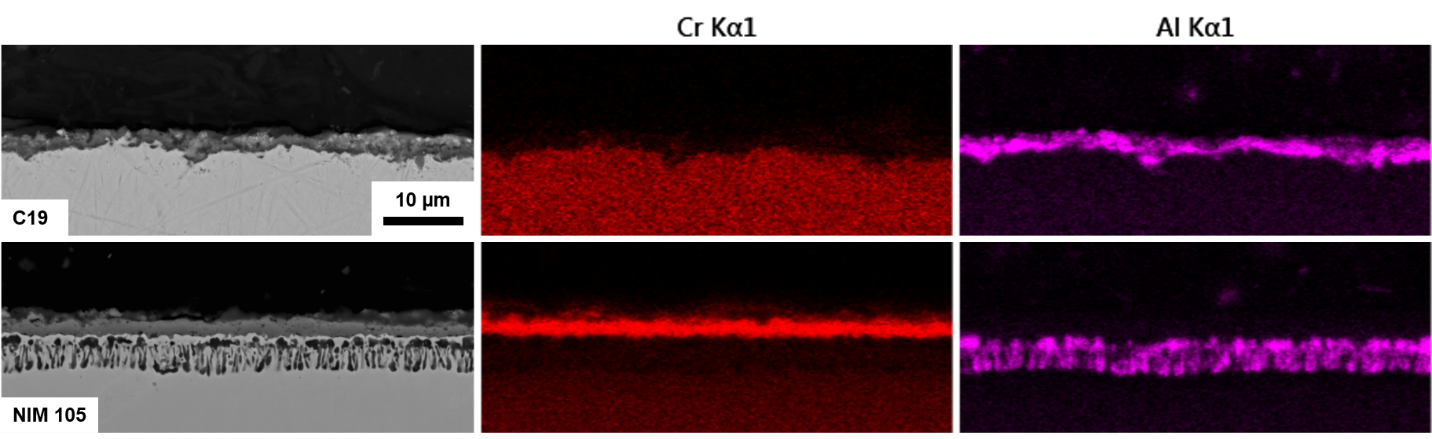

Figure caption: Cross-sectional electron microscopy images and energy-dispersive X-ray elemental concentration maps of Cr and Al for C19 and NIM 105 superalloys following pre-oxidation in air at 1100°C for 1 hour. The C19 superalloy developed a continuous layer of alumina while the commercial NIM 105 superalloy retained an external layer of chromia with discontinuous alumina finger-like intrusions.

Wo, J.W.X., Pang, H.T., Wilson, A.S., Hardy, M.C., Stone, H.J., "The Isothermal Oxidation of a New Polycrystalline Turbine Disk Ni-Based Superalloy at 800 °C and Its Modification with Pre-oxidation", Metall. Mater. Trans. A (2022).